1070 Aluminum Bar

1070 aluminum bar has over 99.7% aluminum content, and minor other impurity elements. So 1070 aluminum bar has good electrical conductivity properties. 1070 aluminum alloy can be formed, cut, and bent through various processing techniques such as cold working and hot working. 1070 aluminum bar is suitable for manufacturing parts with various complex shapes requiring precision.

- Product Description

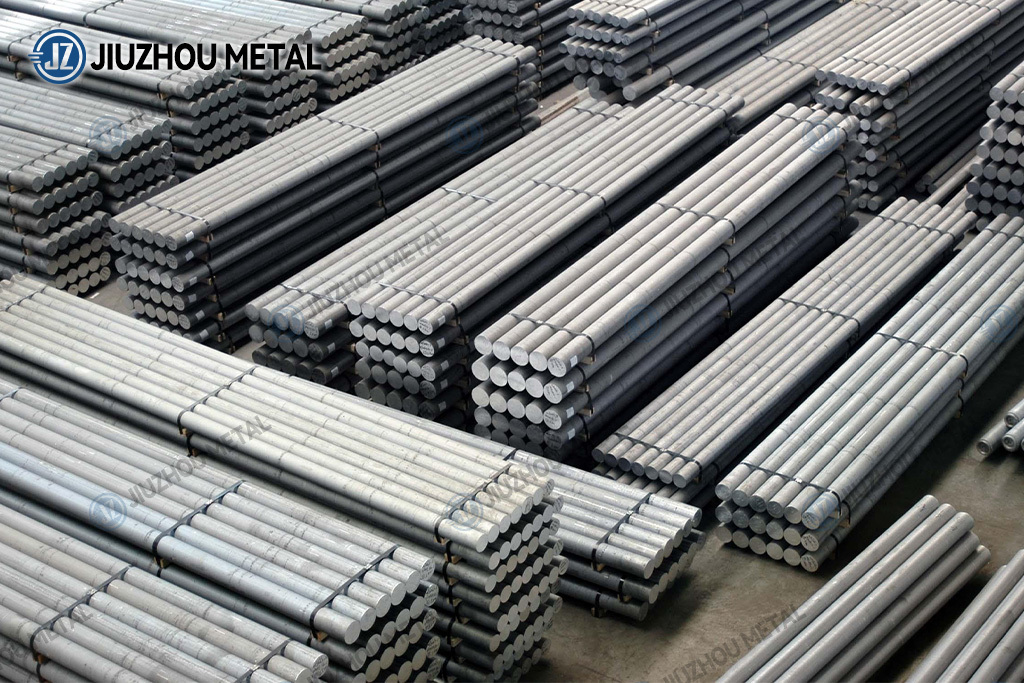

- Spot Warehouse

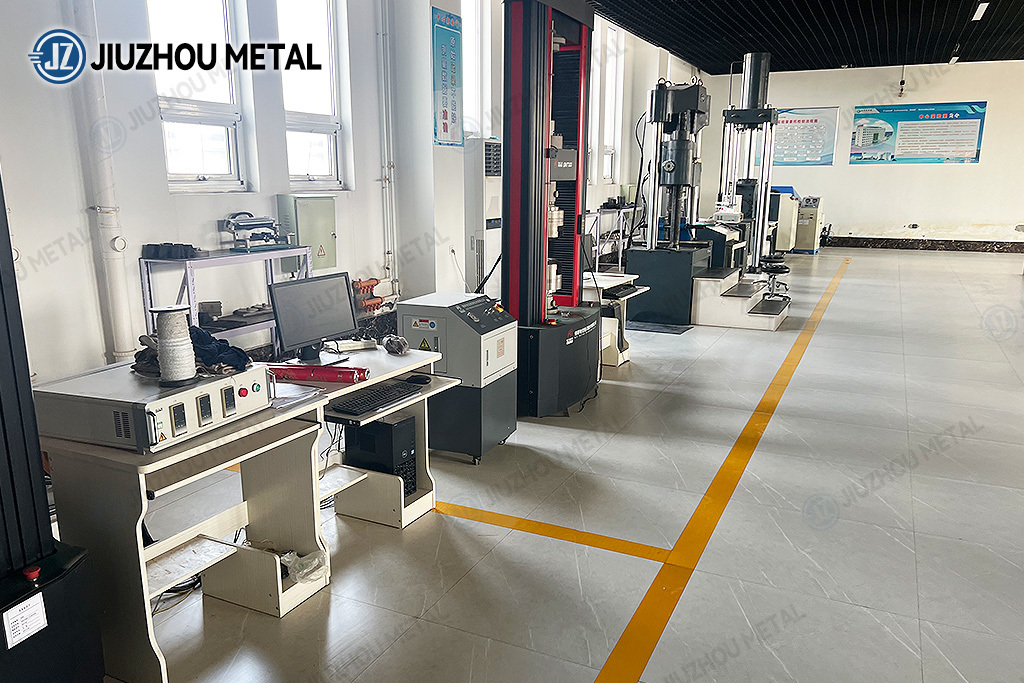

- Product Inspection

- Product Measurement

- Product Packaging

-

- Commodity name: 1070 Aluminum Bar

1070 aluminum bar has over 99.7% aluminum content, and minor other impurity elements. So 1070 aluminum bar has good electrical conductivity properties. 1070 aluminum alloy can be formed, cut, and bent through various processing techniques such as cold working and hot working. 1070 aluminum bar is suitable for manufacturing parts with various complex shapes requiring precision.

1070 Aluminum Bar Description

1070 aluminum bar is made from a pure aluminium alloy as a wrought alloy with a high corrosion resistance and an excellent brazing ability. The complementary elements of 1070 aluminium alloy include aluminium, iron, silicon, zinc, vanadium, copper, titanium, magnesium, and manganese. It has remarkable plasticity and ductility due to the high purity of 1070 aluminum alloy. 1070 aluminum bar has good corrosion resistance and is especially suitable for components, devices and structures that work in hot and humid environments, such as chemical equipment, marine equipment, etc. Lastly, 1070 aluminum bar is widely used in electronics, electrical appliances, automobiles, construction, aviation and other fields.

Product ParametersDiameter

5-650mm or customized

Length

100-2000mm or customized

Certificate

ISO, SGS, BV

Standard

JIS, AISI, ASTM, GB, DIN, EN, etc.

Brand

1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc.

3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc.

5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5754, 5A05, etc.

6000 Series: 6061, 6063, 6082, 6A02, etc.

7000 Series: 7050, 7475, 7075, etc.

8000 Series: 8A06, 8011, 8090, etc.

Surface

Coating, Embossing, Drawing, Polishing, Anodizing, etc.

OEM Service

Punching, Cutting special size, Making flat surface, Surface treatment, etc.

Delivery Time

Received 30% after deposit 7-15 working days

Application

Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields

Sample

Free Offers Sample

Packaging

Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement

Chemical Composition

Alloy

Si

Fe

Cu

Mn

Mg

Cr

Zn

Ti

Others:

Each

Others:

Total

Al: Min.

1050

0.25

0.40

0.05

0.05

0.05

-

0.05

0.03

0.03

-

99.50

1060

0.25

0.35

0.05

0.03

0.03

-

0.05

0.03

0.03

-

99.60

1070

0.20

0.25

0.04

0.03

0.03

-

0.04

0.03

0.05

-

99.70

1100

0.95 Si Fee

0.05~0.20

0.05

-

-

0.1

-

0.05

0.15

99.0

2014

0.5~1.2

0.7

3.9~5.0

0.4~1.2

0.2~0.8

0.10

0.25

0.15

0.05

0.15

Allowance

2017

0.2~0.8

0.7

3.5~4.5

0.4~1.0

0.4~0.8

0.10

0.25

0.15

0.05

0.15

91.5 - 95.5

2024

0.50

0.50

3.8~4.9

0.3~0.9

1.2~1.8

0.10

0.25

0.15

0.05

0.15

Allowance

3003

0.60

0.70

0.05~0.20

1.0~1.5

-

-

0.10

-

0.05

0.15

Allowance

3A21

0.60

0.70

0.20

1.0-1.6

0.05

-

0.15

0.1-0.2

-

-

Allowance

3004

0.30

0.70

0.25

1.0~1.5

0.8~1.3

-

0.25

-

0.05

0.15

Allowance

3005

0.60

0.70

0.30

1.0~1.5

0.2~0.6

0.10

0.25

0.10

0.05

0.15

Allowance

3105

0.60

0.70

0.30

0.3~0.8

0.2~0.8

0.20

0.40

0.10

0.05

0.15

Allowance

5005

0.30

0.70

0.20

0.20

0.5~1.1

0.1

0.25

-

0.05

0.15

Allowance

5052

0.25

0.40

0.10

0.10

2.2~2.8

0.15~0.35

0.10

-

0.05

0.15

Allowance

5754

0.40

0.40

0.10

0.50

2.6~3.6

0.30

0.20

0.15

0.05

0.15

Allowance

5A05

0.50

0.50

0.10

0.3-0.6

4.8-5.5

-

0.20

-

0.05

0.05

Allowance

5083

0.40

0.40

0.10

0.4~1.0

4.0~4.9

0.05~0.25

0.25

0.15

0.05

0.15

Allowance

6061

0.40~0.8

0.70

0.15~0.4

0.15

0.8~1.2

0.04~0.35

0.25

0.15

0.05

0.15

Allowance

6082

0.70~1.3

0.50

0.10

0.4~1.0

0.6~1.2

0.25

0.20

0.10

0.05

0.15

Allowance

7075

0.40

0.50

1.2~2.0

0.30

2.1~2.9

0.18~0.28

5.1~6.1

0.20

0.05

0.15

Allowance

Mechanical Properties

Tensile Strength

(MPa)

Elongation Rate

(%)

Yield Strength

(MPa)

≥75

≥ 4.5

≥35

Physical Performance

Density

Melting Point

Modulus of Elasticity

Thermal Conductivity

Thermal Expansion

2.7 Kg/m³

640 °C

68 GPa

230 w/m K

23×10-6/K

Annealing State

Brand

Annealing State

1xxx: 1050, 1050A, 1060, 1100

O, H12, H14, H16, H18, H22, H24, H26, H28, H111

3xxx: 3003, 3004, 3005, 3105

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454

O, H22, H24, H26, H28, H32, H34, H36, H38, H111

6xxx: 6061, 6082

T4, T6, T451, T651

2xxx: 2024

T3, T351, T4

7xxx: 7075

T6, T651

Scope of Application

Aluminum Uses And Application Area

Food Packaging

Beverage can ends, cans, bottle caps, etc.

Building

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc.

Transportation

Auto parts, passenger car bodies, aviation ships and air cargo containers.

Electronic Equipment

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc.

Consumer Goods

Umbrellas, cooking utensils, sports equipment, etc

Other

Military, color coated aluminum plate

-

1070 Aluminum Bar - Stock Warehouse

-

1070 Aluminum Bar - Product Inspection

Tensile Strength Testing Tensile Strength Testing Physical Performance Testing Chemical Composition Testing

Inspection Hardness Testing Spectral Detection Mechanical Properties -

1070 Aluminum Bar - Product Measurement

Outer Diameter Measurement Outer Diameter Measurement Outer Diameter Measurement Outer Diameter Measurement -

1070 Aluminum Bar - Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote