Inconel 600 Bar

Inconel 600 bar is made of a nickel-based superalloy known for its excellent heat resistance, corrosion resistance and high strength in extreme environments. This bar is widely used in the chemical, aerospace, heat treatment and power industries, especially in high-temperature applications that require resistance to oxidizing and reducing environments.

- Product Description

- Spot Warehouse

- Product Inspection

- Product Measurement

- Product Packaging

-

- Commodity name: Inconel 600 Bar

Inconel 600 bar is made of a nickel-based superalloy known for its excellent heat resistance, corrosion resistance and high strength in extreme environments. This bar is widely used in the chemical, aerospace, heat treatment and power industries, especially in high-temperature applications that require resistance to oxidizing and reducing environments.

Inconel 600 Bar Description

Inconel 600 alloy is mainly composed of nickel and chromium. In addition, the alloy contains a smaller proportion of iron, as well as trace amounts of silicon, carbon and manganese. This unique chemical composition gives Inconel 600 bars excellent corrosion resistance and mechanical strength at high temperatures. Inconel 600 alloy exhibits excellent mechanical properties over a wide temperature range and is capable of use at temperatures up to 1093°C (2000°F) while maintaining good creep and fracture resistance. Its corrosion resistance is particularly outstanding and it can resist a variety of corrosive media, including seawater, organic acids, and high-temperature and high-pressure steam environments.

Product Parameters

Product Name

Inconel 600 Bar

Outer Diameter

Round Bar

4mm-500mm

Hexagon Bar

18mm-57mm (11/16″ to 2-3/4″)

Square Bar

18mm-47mm (11/16″ to 1-3/4″)

Flat Steel

1/2 "to 10", Thickness: 2mm-150mm, Can provide customized

Length

1-6 meters, Length can be customized

Standard

ASTM, AISI, JIS, GB, DIN, EN, etc.

Surface

Black, Bright Polished, Rough Turning, Matt Surface Treatment, NO.4, BA, etc.

Certificate

ISO, SGS, BV

Production Technology

Hot Rolling, Cold Rolling

Chemical Composition

C

Si

S

Cr

Mn

Fe

Ni

Cu

0.15 max

0.5 max

0.015 max

14.0 - 17.0

1.0 max

6.0 - 10.0

72.0 min

0.5 max

Mechanical Properties

Tensile Strength (ksi)

0.2% Yield Strength (ksi)

Elongation% in 2 inches

110

85

10

Physical Performance

Units

Temperature in°C

Density

8.47 g/cm³

Room

Specific Heat

0.106 Kcal/kg.C

22°

Melting Range

1354-1413°C

-

Modulus of Elasticity

214 KN/mm²

22°

Electrical Resistivity

103 µΩ.cm

Room

Coefficient of Expansion

13.3 µm/m °C

20 - 100°

Thermal Conductivity

14.9 w/m-° K

20°

Scope of Application

The average utilization of this nickel alloy includes the chemical, pulp and paper, aerospace, nuclear engineering and heat treatment industries.

-

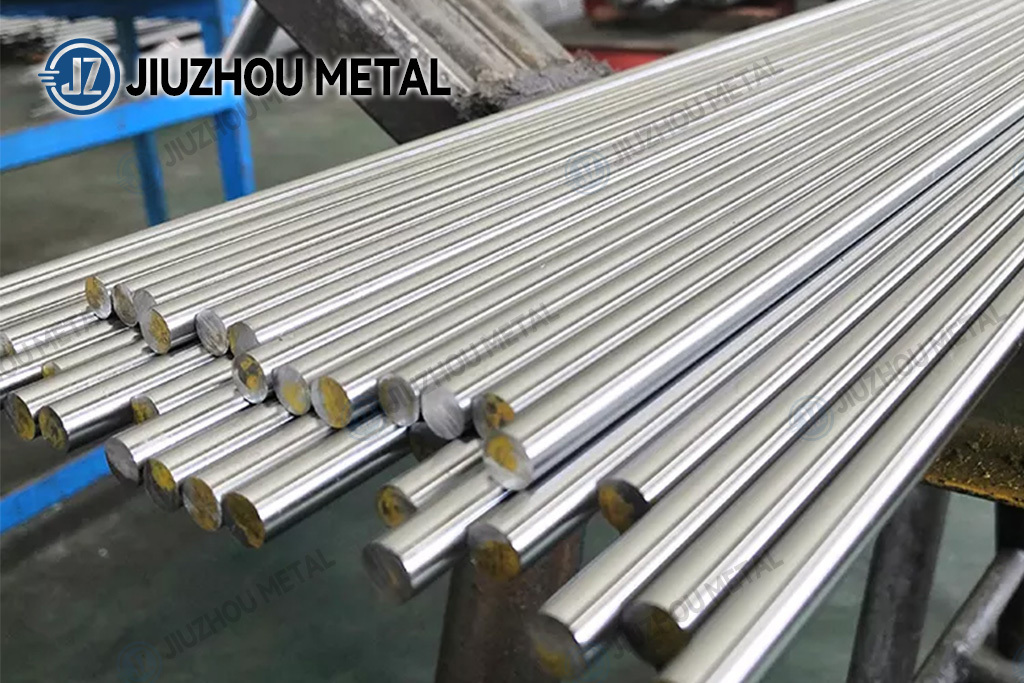

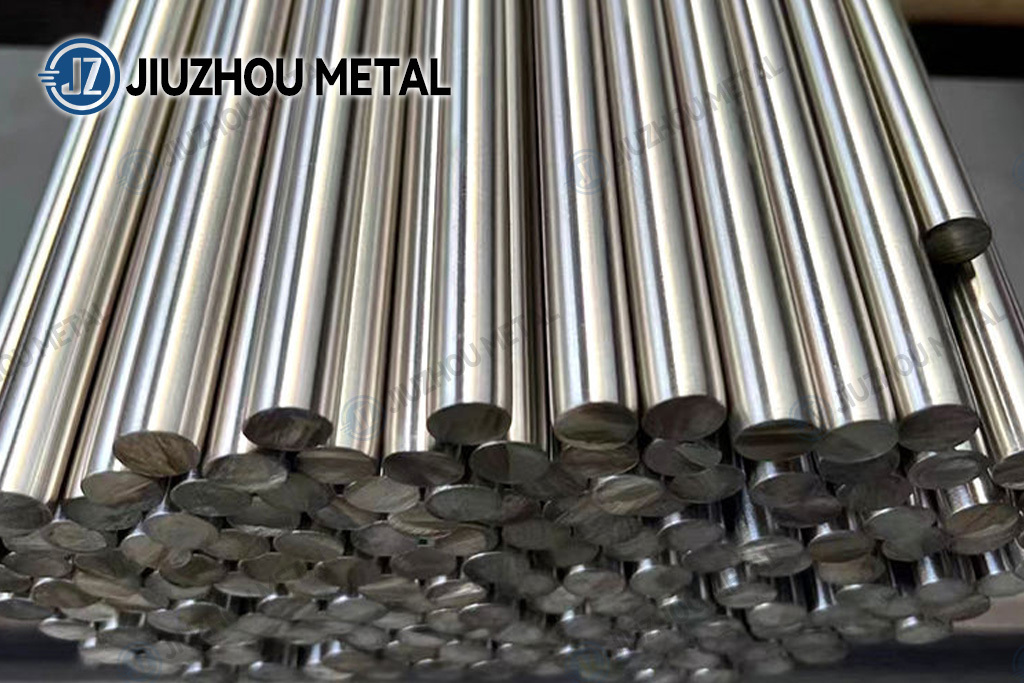

Inconel 600 Bar - Stock Warehouse

-

Inconel 600 Bar - Product Inspection

Tensile Strength Testing Tensile Strength Testing Physical Performance Testing Chemical Composition Testing

Inspection Hardness Testing Spectral Detection Mechanical Properties -

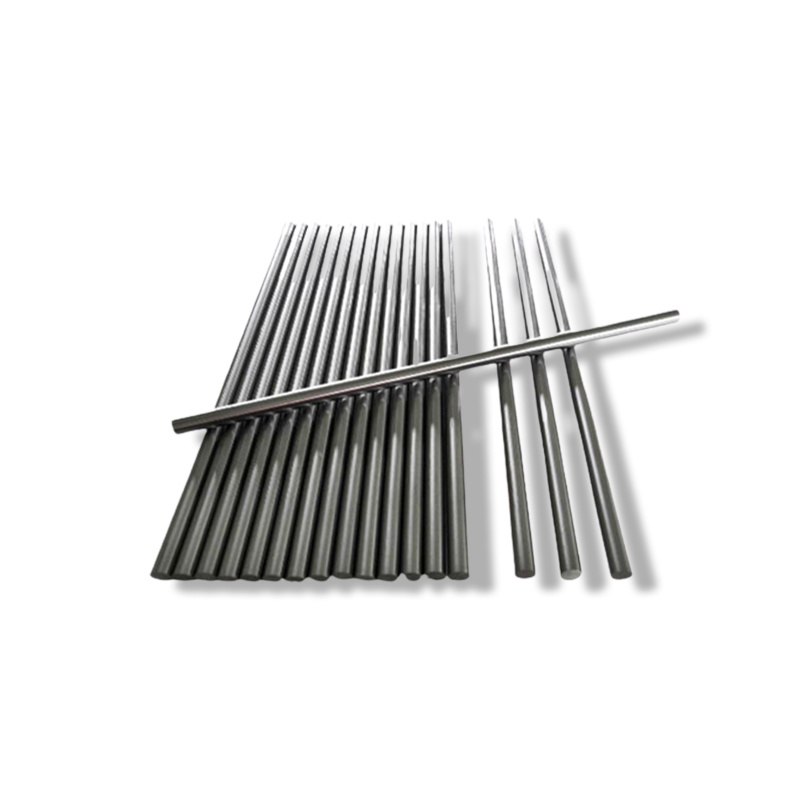

Inconel 600 Bar - Product Measurement

Outer Diameter Measurement Outer Diameter Measurement Outer Diameter Measurement Outer Diameter Measurement -

Inconel 600 Bar - Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote