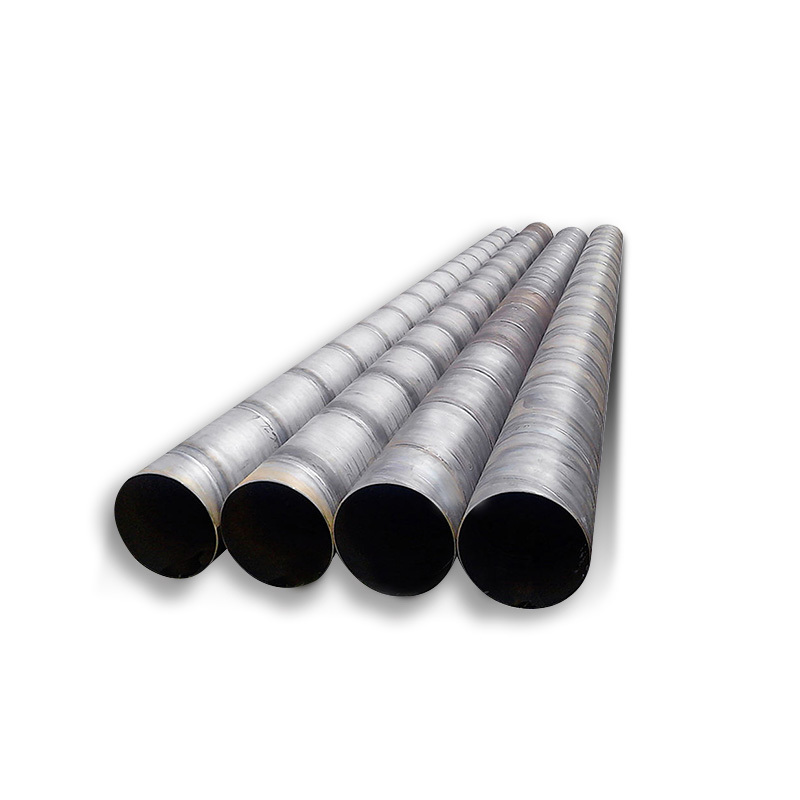

A335 Seamless Steel Pipe

ASTM A335 steel pipe may be hot finished or cold drawn and subjected to the following finishing heat treatment. The specification covers "chrome-molybdenum" seamless pipes with excellent corrosion resistance and high temperature tensile strength.

- Product Description

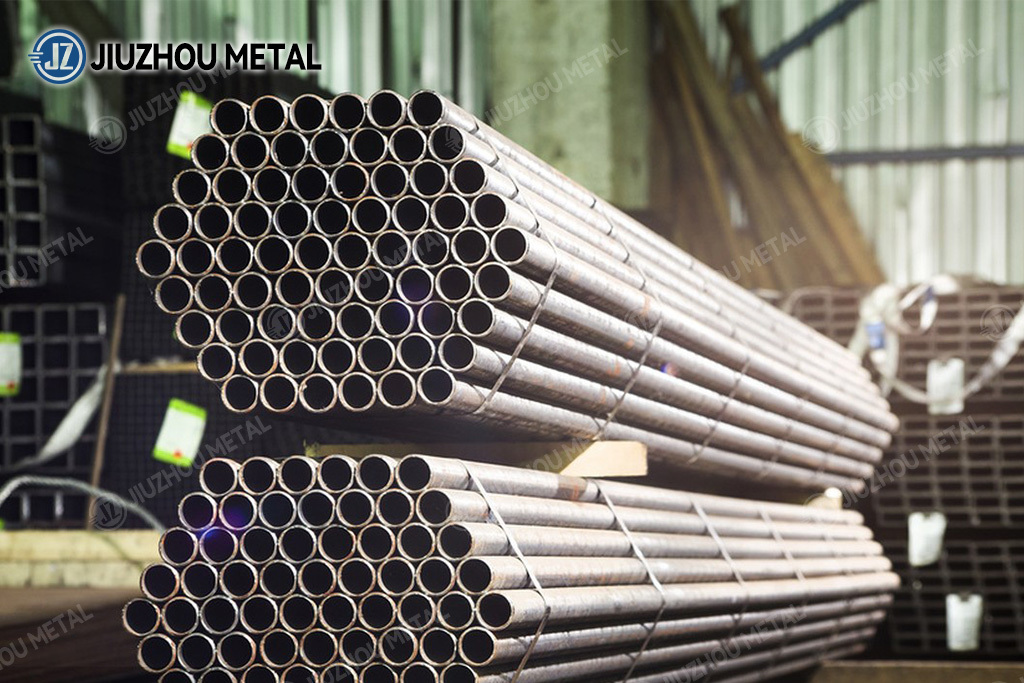

- Spot Warehouse

- Product Inspection

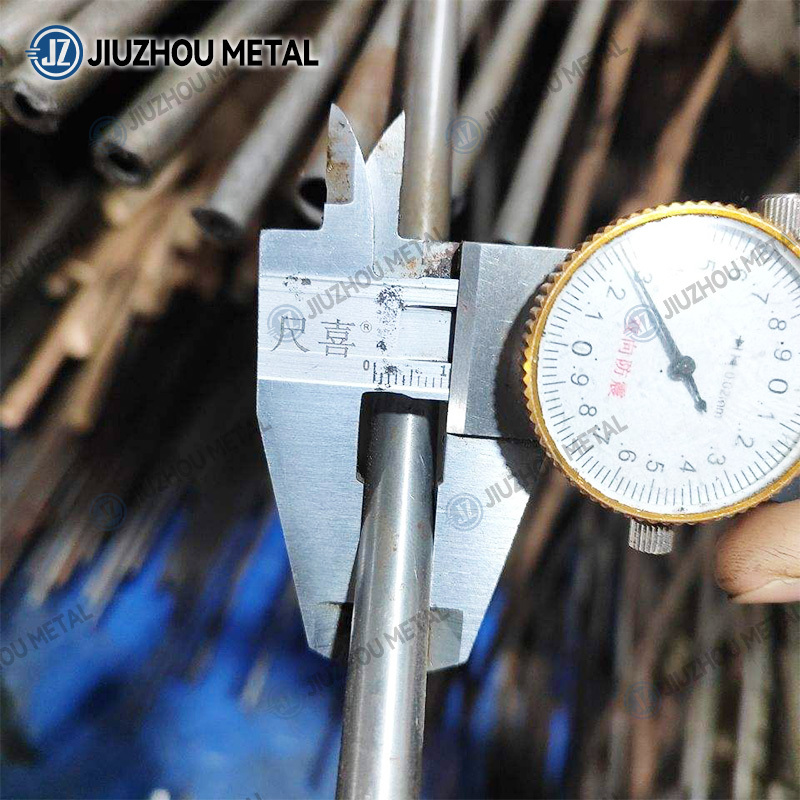

- Product Measurement

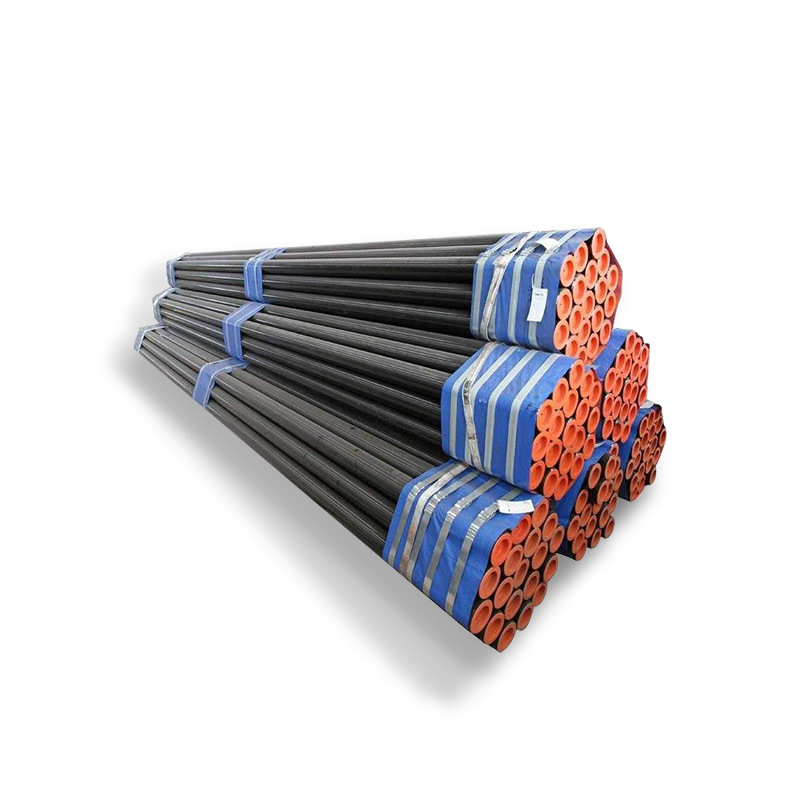

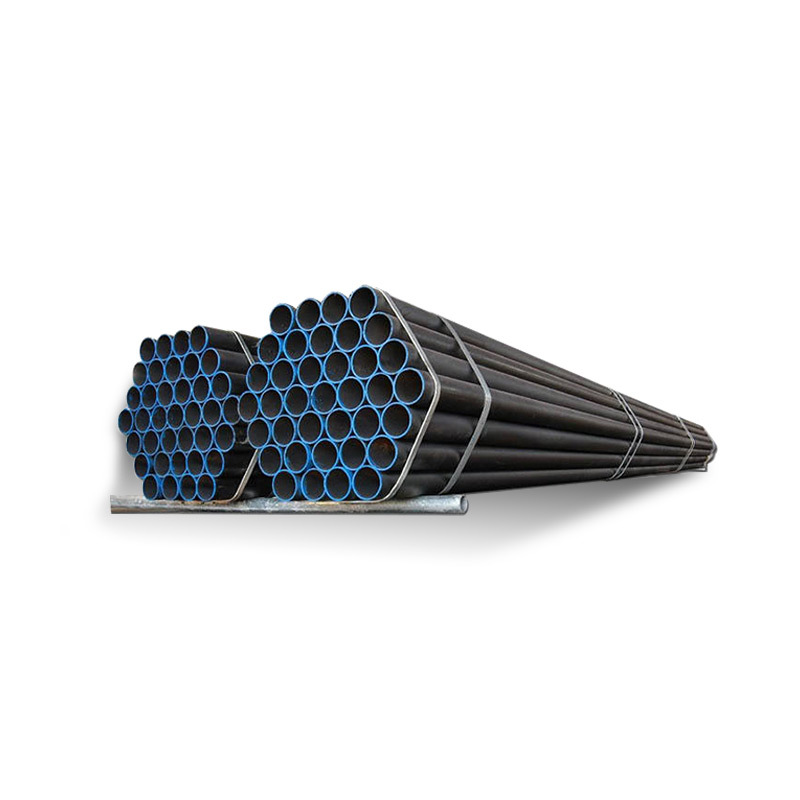

- Product Packaging

-

- Commodity name: A335 Seamless Steel Pipe

ASTM A335 steel pipe may be hot finished or cold drawn and subjected to the following finishing heat treatment. The specification covers "chrome-molybdenum" seamless pipes with excellent corrosion resistance and high temperature tensile strength.

A335 Seamless Steel Pipe Description

ASTM A335 Pipe is a seamless ferritic alloy-steel Pipe for high temperature service. Pipe of this specification are suitable for bending, flanging, and similar forming operations, and for fusion welding. Generally, ASTM A335 P11, P22, and P91 pipelines are used for power generation and downstream oil and gas, and P5 and P9 grades are used for refinery applications. A335 steel pipe not only has high oxidation resistance and high temperature steam corrosion resistance,but also has good impact toughness,stable durable plasticity and thermal strength. A335 steel pipes are commonly used to transport high-temperature and high-pressure oil, natural gas and other media.

Product ParametersProduct Name

A335 Seamless Steel Pipe

Standard

EN/DIN/JIS/ASTM/BS/ASME/AISI etc.

Outer Diameter

Seamless: 1/4"-36"

Welding: 21.3mm-3620mm

Round Tube: 1/2"-10"

Square Tube/Rectangular Tube: 15x15mm-400x600mm

Wall Thickness

Seamless: 1.25mm-50mm

Welding: 1.65mm-65mm

Length

3-12 meters, Support customization

Surface Process

Bright, Polished, Black

Other Services

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc.

Chemical Composition

A335

UNS

C ≤

Mn

P ≤

S ≤

Si ≤

Cr

Mo

P1

K11522

0.10-0.20

0.30-0.80

0.025

0.025

0.10-0.50

-

0.44-0.65

P2

K11547

0.10-0.20

0.30-0.61

0.025

0.025

0.10-0.30

0.50-0.81

0.44-0.65

P5

K41545

0.15

0.30-0.60

0.025

0.025

0.5

4.00-6.00

0.44-0.65

P5b

K51545

0.15

0.30-0.60

0.025

0.025

1.00-2.00

4.00-6.00

0.44-0.65

P5c

K41245

0.12

0.30-0.60

0.025

0.025

0.5

4.00-6.00

0.44-0.65

P9

S50400

0.15

0.30-0.60

0.025

0.025

0.50-1.00

8.00-10.00

0.44-0.65

P11

K11597

0.05-0.15

0.30-0.61

0.025

0.025

0.50-1.00

1.00-1.50

0.44-0.65

P12

K11562

0.05-0.15

0.30-0.60

0.025

0.025

0.5

0.80-1.25

0.44-0.65

P15

K11578

0.05-0.15

0.30-0.60

0.025

0.025

1.15-1.65

-

0.44-0.65

P21

K31545

0.05-0.15

0.30-0.60

0.025

0.025

0.5

2.65-3.35

0.80-1.60

P22

K21590

0.05-0.15

0.30-0.60

0.025

0.025

0.5

1.90-2.60

0.87-1.13

P91

K91560

0.08-0.12

0.30-0.60

0.02

0.01

0.20-0.50

8.00-9.50

0.85-1.05

P92

K92460

0.07-0.13

0.30-0.60

0.02

0.01

0.5

8.50-9.50

0.30-0.60

Mechanical Properties

A335

UNS

Yield Strength Ksi

Tensile Strength Ksi

Elongation %

P1

K11522

30

55

30

P2

K11547

30

55

30

P5

K41545

40

70

30

P9

S50400

30

60

30

P11

K11597

30

60

20

P12

K11562

32

60

30

P22

K21590

30

60

30

P91

K91560

60

85

20

Scope of Application

The specification covers "chrome-molybdenum" seamless pipes with excellent corrosion resistance and high temperature tensile strength. Generally, ASTM A335 P11, P22, and P91 pipelines are used for power generation and downstream oil and gas, and P5 and P9 grades are used for refinery applications.

-

A335 Seamless Steel Pipe - Stock Warehouse

-

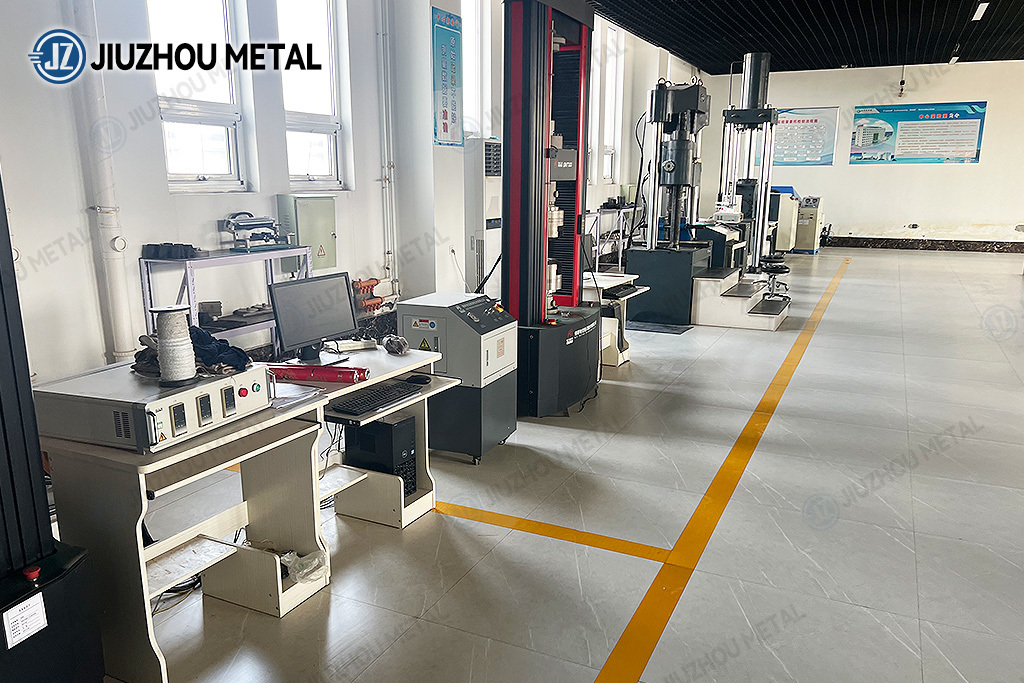

A335 Seamless Steel Pipe - Product Inspection

Tensile Strength Testing Tensile Strength Testing Physical Performance Testing Chemical Composition Testing

Inspection Hardness Testing Spectral Detection Mechanical Properties -

A335 Seamless Steel Pipe - Product Measurement

Width Measurement Length Measurement Thickness Measurement Thickness Measurement -

A335 Seamless Steel Pipe - Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote