DT8/DT9 Pure Iron

Pure iron is the earliest and commonly used pure metal soft magnetic material. Pure iron is referring to the low-carbon steel with a purity of over 99.85% iron and a maximum carbon content of 0.04%. In addition to the excellent steel cleanliness, pure iron also has many distinctive characteristics including outstanding corrosion resistance, admirable hot/cold forming capability, low smelting cost and suitable for all types of welding.

- Product Description

- Spot Warehouse

- Product Inspection

- Product Measurement

- Product Packaging

-

- Commodity name: DT8/DT9 Pure Iron

Pure iron is the earliest and commonly used pure metal soft magnetic material. Pure iron is referring to the low-carbon steel with a purity of over 99.85% iron and a maximum carbon content of 0.04%. In addition to the excellent steel cleanliness, pure iron also has many distinctive characteristics including outstanding corrosion resistance, admirable hot/cold forming capability, low smelting cost and suitable for all types of welding.

DT8/DT9 Pure Iron Description

It is a kind of high quality steel with iron content above 99.5%, which is a low carbon, low sulfur and low phosphorus iron. Industrial pure iron is mainly used for electromagnetic relays, pure iron for iron core, soft magnetic pure iron, pure iron for magnetic powder clutch, pure iron for electronic lock, electric iron for automobile piston, pure iron belt for magnetic shielding, aviation instrumentation, Military pure iron, pure iron plate for galvanizing pot, pure iron sheet for electronic components, solenoid valve, pure iron for magnetic separator, no hairline pure iron, pure iron for electronic tube, easy to turn electrician pure iron.

Electromagnetic Properties of Pure Iron Grade Coercivity Hc (A/m) Maximum permeability μmax (mH/m) Magnetic flux density B (T) B200 B300 B500 B1000 B2500 B5000 B10000 DT4 ≤ 96.0 ≥ 7.50 1.20 1.30 1.40 1.50 1.62 1.71 1.80 DT4A ≤ 72.0 ≥ 10.00 DT3E ≤ 48.0 ≥ 12.50 DT4C ≤ 32.0 ≥ 15.00 DT8 ≤ 96.0 ≥ 7.50 – – 1.40 1.50 1.62 1.71 1.80 DT8A ≤ 72.0 ≥ 8.75 DT9E ≤ 64.0 ≥ 17.50 – – 1.50 1.57 1.64 1.71 1.80 Chemical Composition

Denuo Pure Iron

Chemical Composition (Mass Fraction) (%) ≤

C

Si

Mn

P

S

Al

Cr

Ni

Cu

DT3/DT3A

0.04

0.20

0.30

0.020

0.020

0.50

0.10

0.20

0.20

DT4/DT4A/DT4E/DT4C

0.025

0.20

0.30

0.020

0.020

0.15~0.50

0.10

0.20

0.20

SUYP/SUYB

0.008

0.05

0.20

0.020

0.020

0.15~0.50

0.05

0.10

0.10

Physical Performance

Density at 20 °C 7,86 kg/dm³ Elastic modulus 207 kN/mm² Linear thermal expansion coefficient

temperature range 0° C-100° C12·10-6 1/°C Melting point 1.536 °C Scope of Application

● Magnetic Shielding

● Aviation and Nuclear Industry

● Production of magnets (yokes, pole cores and armatures) -

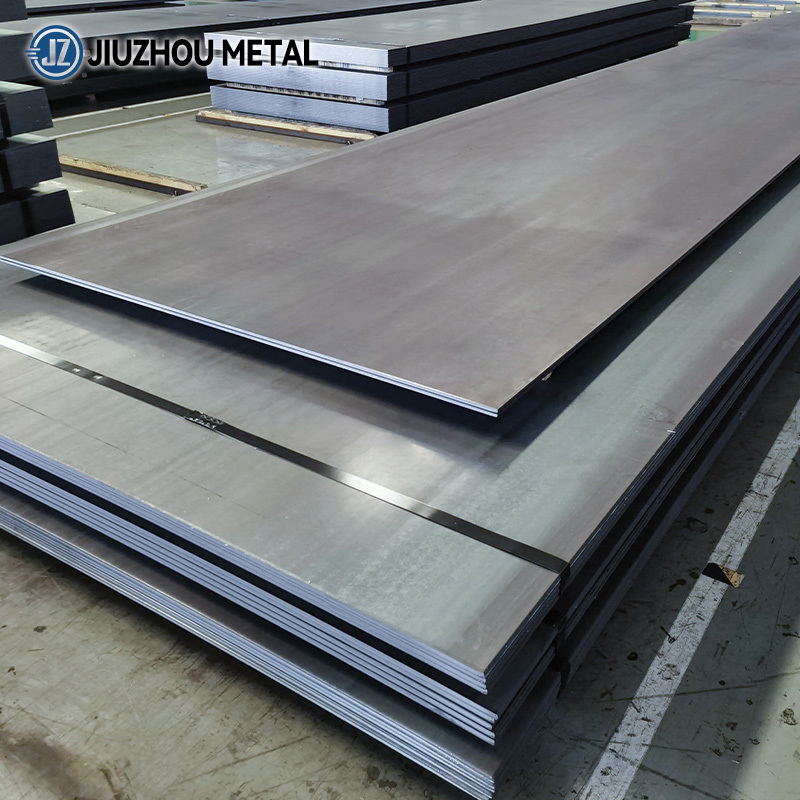

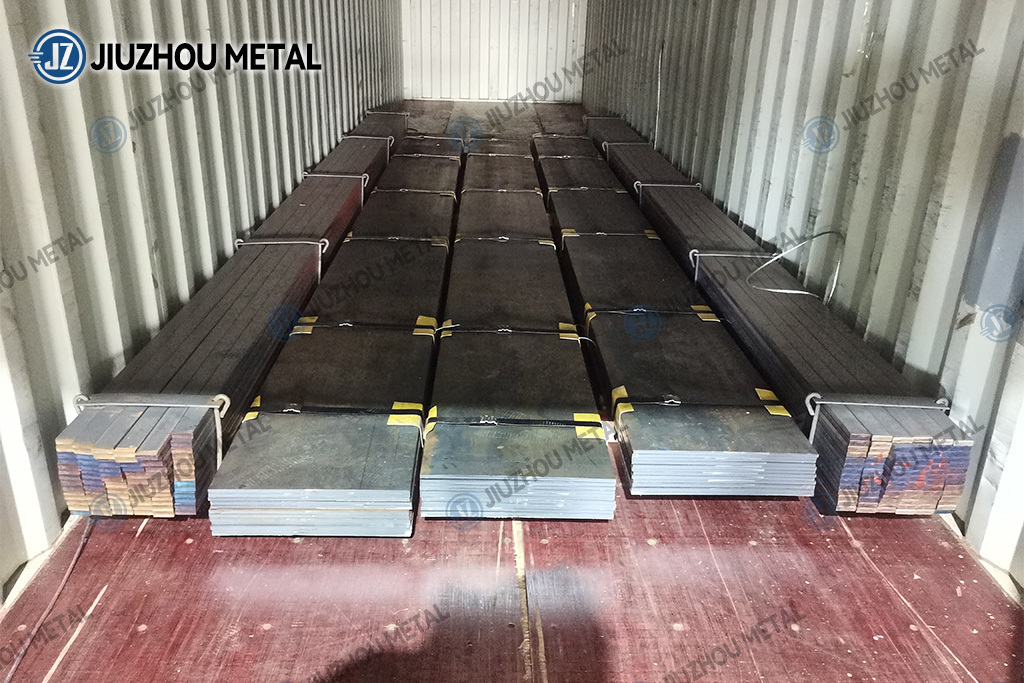

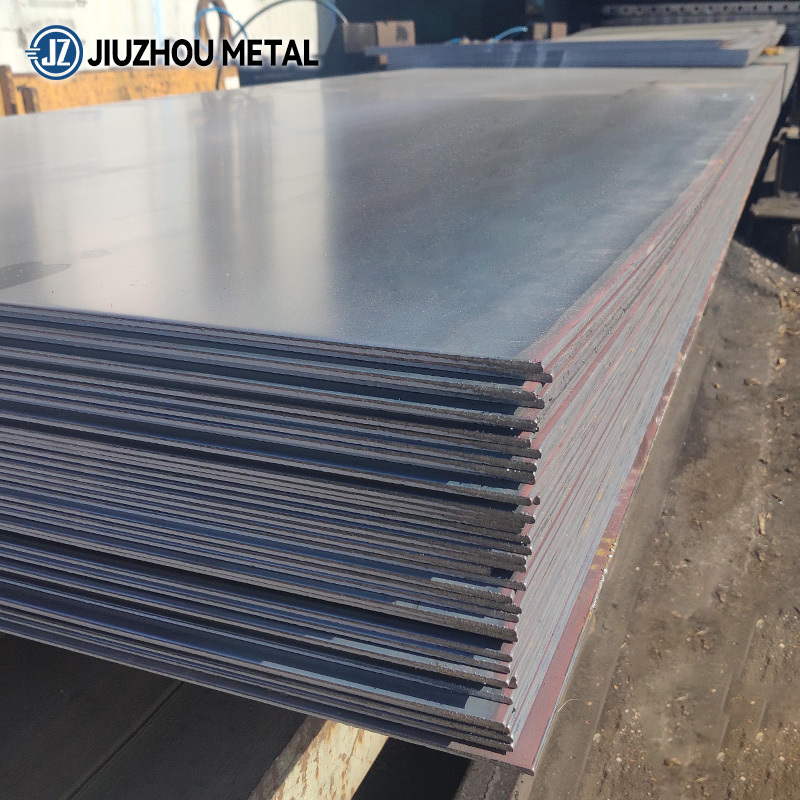

DT8/DT9 Pure Iron - Stock Warehouse

-

DT8/DT9 Pure Iron - Product Inspection

Tensile Strength Testing Tensile Strength Testing Physical Performance Testing Chemical Composition Testing

Inspection Hardness Testing Spectral Detection Mechanical Properties -

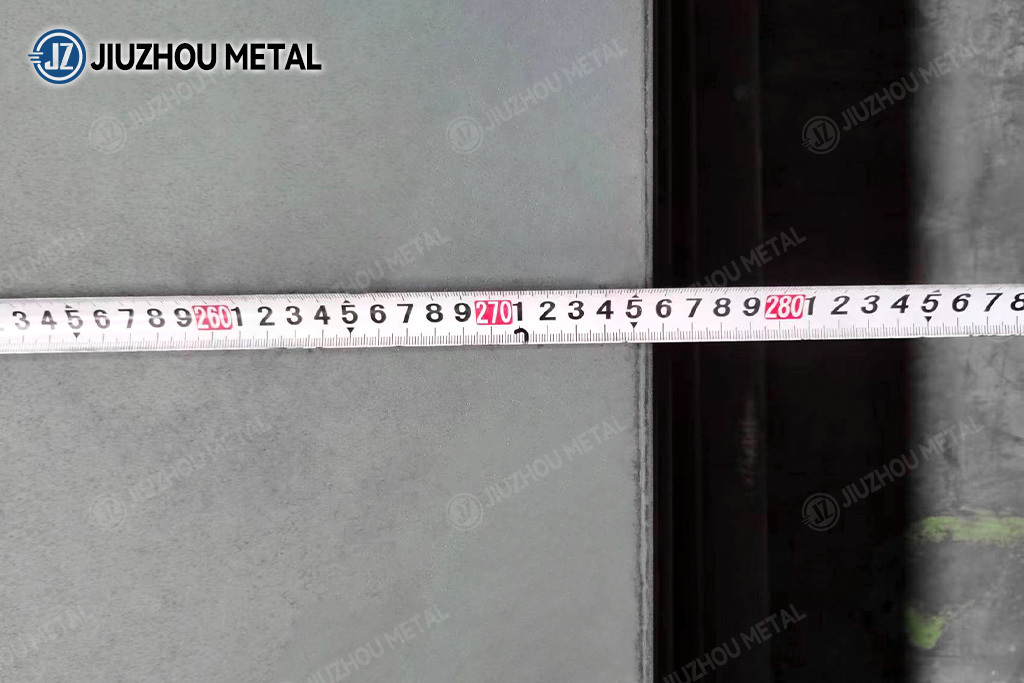

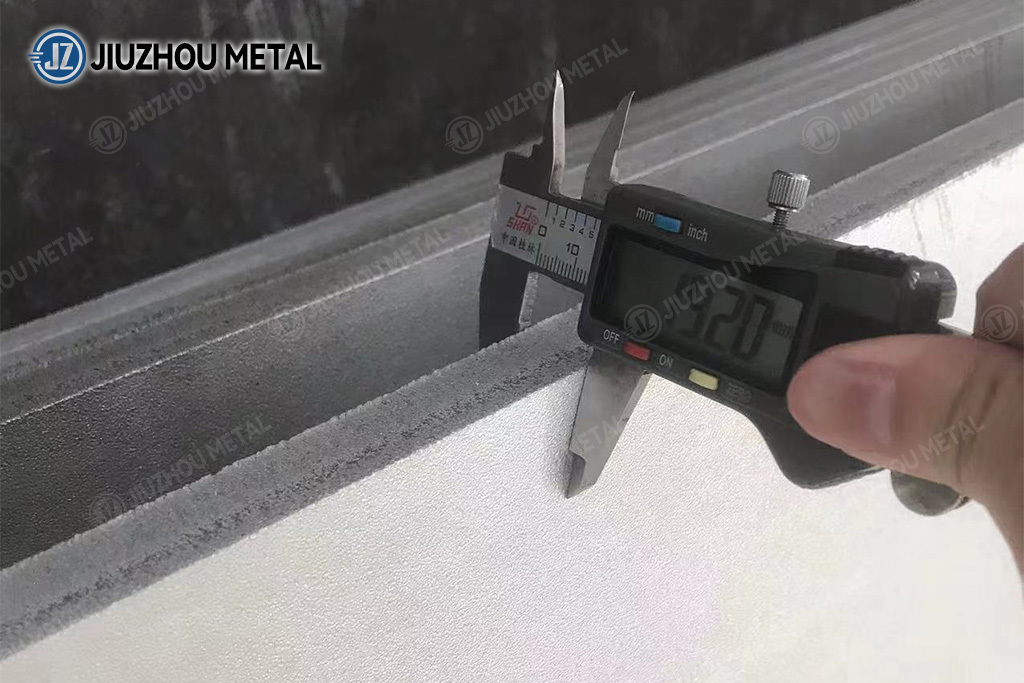

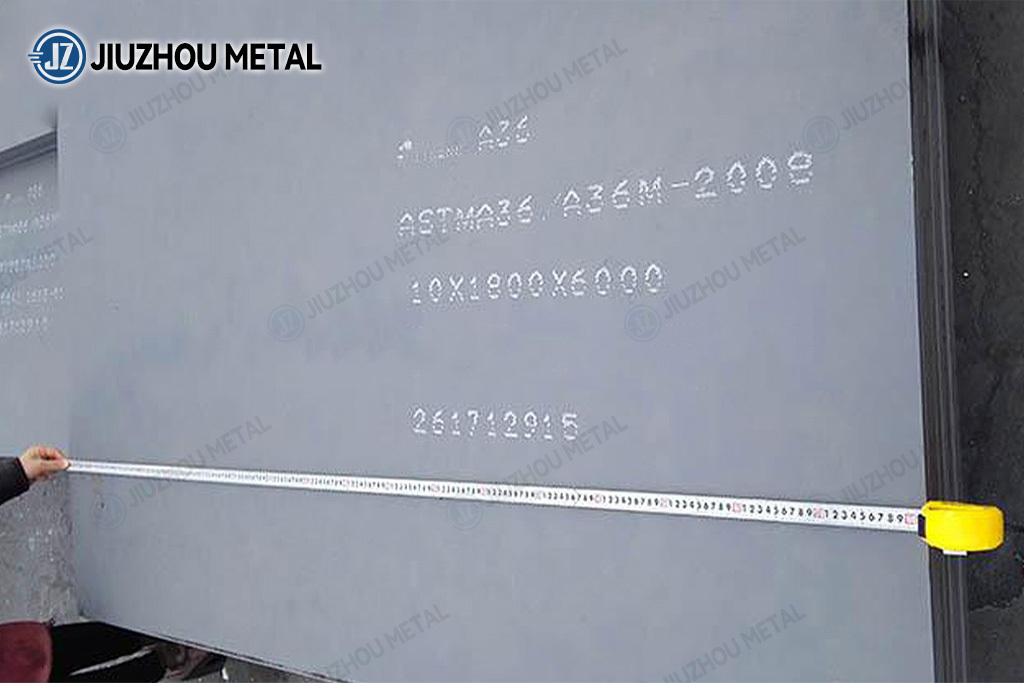

DT8/DT9 Pure Iron - Product Measurement

Width Measurement Length Measurement Thickness Measurement Thickness Measurement -

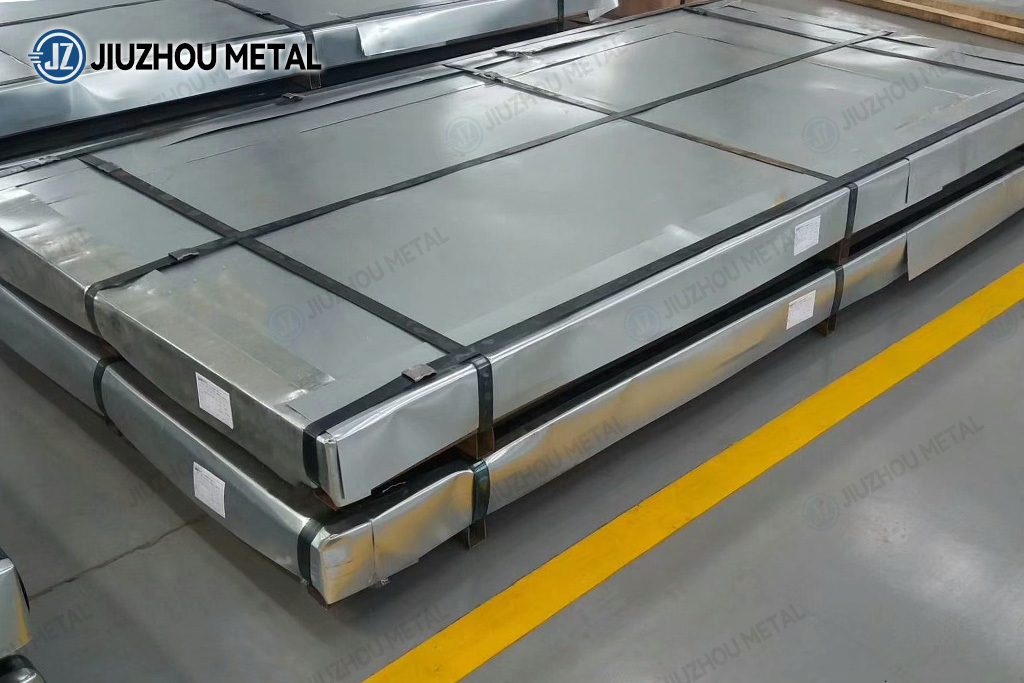

DT8/DT9 Pure Iron- Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote