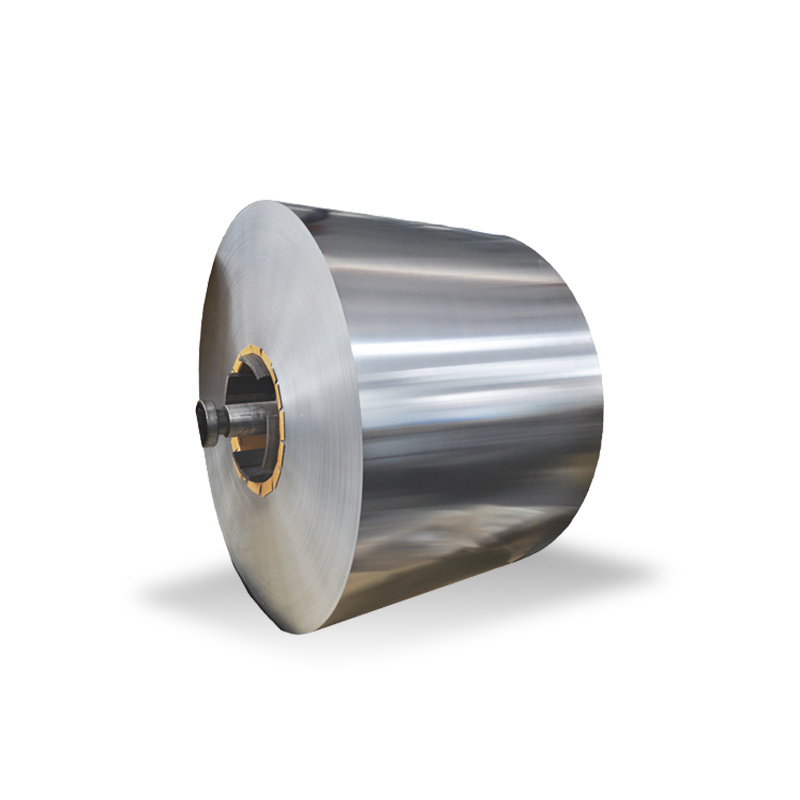

Single Reduced Cold-Rolled Tinplate Coil

Single reduced cold-rolled tinplate coil refers to those steel coils where the steel substrate has been reduced to the desired thickness in a cold-reduction mill and subsequently annealed and temper rolled.

- Product Description

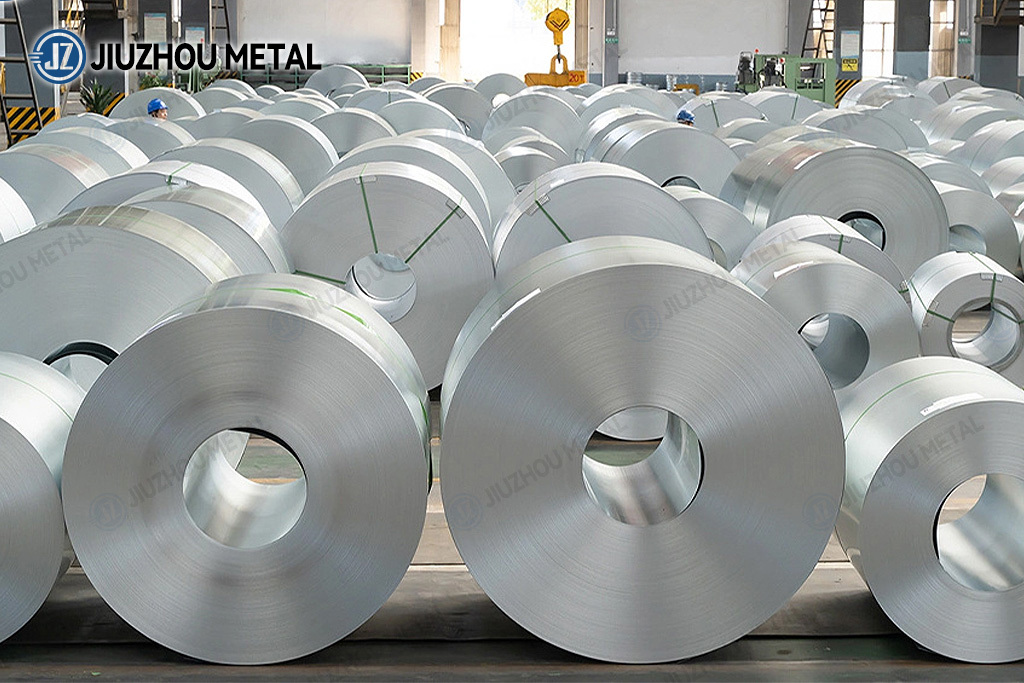

- Spot Warehouse

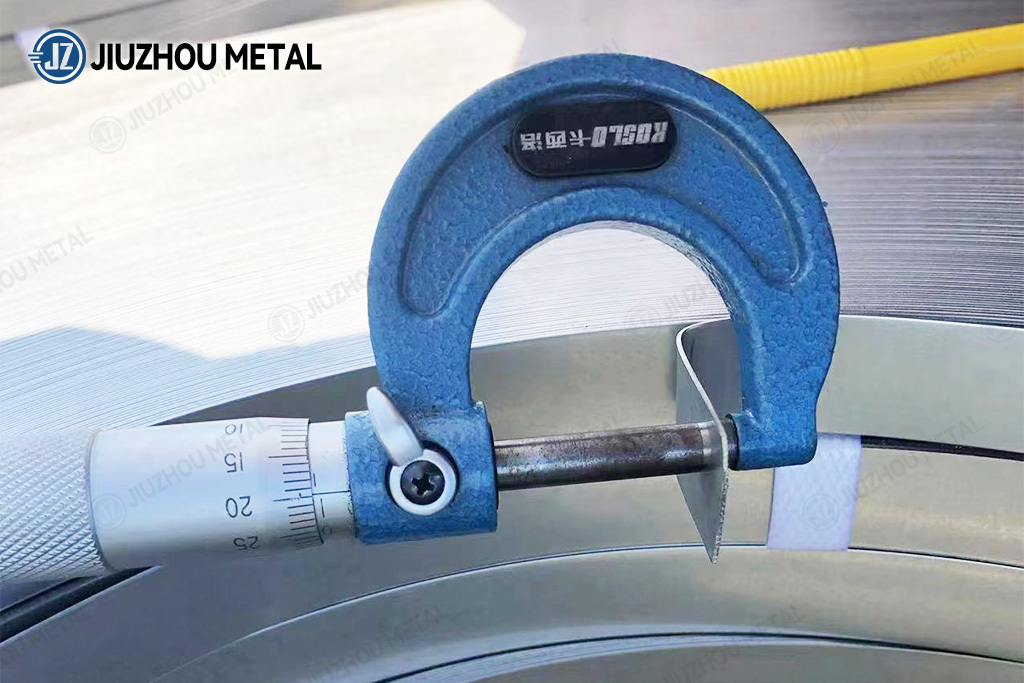

- Product Inspection

- Product Measurement

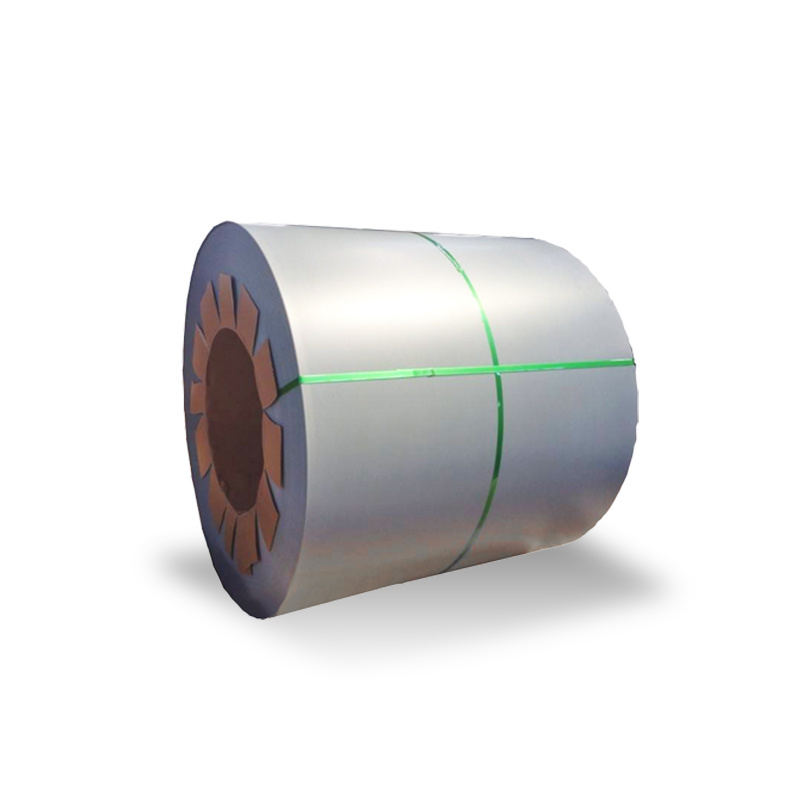

- Product Packaging

-

- Commodity name: Single Reduced Cold-Rolled Tinplate Coil

Single reduced cold-rolled tinplate coil refers to those steel coils where the steel substrate has been reduced to the desired thickness in a cold-reduction mill and subsequently annealed and temper rolled.

Single Reduced Cold-Rolled Tinplate Coil Description

Tin-plated steel coil, commonly known as tinplate coil is a steel product with a stampable thin steel coil as the base, tin plating on the surface, and multiple protective films. It has the characteristics of corrosion resistance, non-toxic, odorless, glossy surface, light weight, high strength. In addition, it is easy to weld and process, and has strong adaptability to ambient temperature. Single cold-reduced tinplate coil can be supplied with either a bright, silver, stone or matt finish, and the finish required shall be specified at the time of ordering. Single reduced cold-rolled tinplate coil is generally specified in nominal thicknesses that are multiples of 0,005 mm, from 0,150 mm up to and including 0,600 mm. It is widely used in food, beverage, grease, chemical, paint, paint, aerosol cans, bottle caps and many other daily necessities packaging.

Product ParametersProduct Name

Single Reduced Cold-Rolled Tinplate Coil

Thickness

0.18mm-0.50mm

Width

260mm-980mm

Length

Support customization

Tin Coating

General: 2.8g or 5.6g, can be produced according to your needs

Substrate Type

MR / SPCC / L / D

Reference Standard

GB/T 2520, JIS G3303, JIS G3315, DIN EN 10202, DIN EN 10203

Surface State of Tinplate

Surface State

Features

Light Surface

Electroplated tin smooth raw material strip after melting treatment to obtain the glaze,Smooth surface with very fine grindstone pattern

Stonetextured Surface

Electroplating tin raw material with the glaze obtained after melting treatment,Grindstone pattern with certain direction

Silvercolor Surface

Electroplating tin raw material with the glazed surface obtained after melting treatment, the surface is rough and dull

Mattless Surface

The surface of the substrate is rough and dull, and the tin plating layer is not soft melting

Substrate Type

Substrate Type

Introduction

MR

The most general steel, steelmaking impurity residue less, excellent mechanical properties and corrosion resistance

L

Used for the production of acidic contents (oranges, yellow peaches, pineapples, etc.), and the inner surface of the food cans for iron high corrosion resistance tinplate substrate steel, such tinplate is often calledKPlate

D

Used to produce two pieces of high-processing tin plate substrate steel, such tin plate is often called.DIMaterial

SPCC

Chinese characteristics, using ordinary hot rollingSPHCProduces, usually used for miscellaneous tank purposes.

Coating Weight

Classification

Representation of Tin Coating Weight

Tin Plating Nominal Weight (g/m2)

Minimum Average Tin Plating Weight (g/m2)

Equal Tin Plating (E)

1.1/1.1

1.1/1.1

1.8

2.2/2.2

2.2/2.2

4.0

2.8/2.8

2.8/2.8

5.0

5.6/5.6

5.6/5.6

10.5

Differentiated Tin Plating (D/A)

2.2/1.1

2.2/1.1

2.0/0.9

2.8/1.1

2.8/1.1

2.25/0.9

5.6/1.1

5.6/1.1

5.05/0.9

2.8/2.2

2.8/2.2

2.25/2.0

5.6/2.2

5.6/2.2

5.05/2.0

5.6/2.8

5.6/2.8

5.05/2.25

Chemical Composition

No.

C

Si

Mn

S

P

Cu

Ni

Cr

Mo

D

0.12

0.03

0.6

0.05

0.02

0.2

0.15

0.1

0.05

L

0.13

0.03

0.6

0.05

0.15

0.03

0.04

0.06

0.05

MR

0.13

0.03

0.6

0.05

0.2

0.2

0.2

0.1

0.05

Mechanical Properties & Applications

Standard Name

Nominal Hardness HR30TS

Strong Yield MPA

Scope of Application

T-1

49

230 /-50

Drawing requirements, drawn ironing cans, nozzles, nozzles, closures

T-2

53

245 /-50

Ring and plug, dome, closure, shallow pull and special tank parts

T-2.5

55

260 /-50

Battery cell, small can cover and body

T-3

57

275 /-50

Cans and cans, large diameter caps, crown caps

T-3.5

59

290 /-50

Can body, closure and crown lid

T-4

61

340 /-50

Can body, closure and crown lid

T-5

65

480 /-50

Cans and cans

Ordering Notes

The ordering elements for tin plating generally include: standard grade (including steel grade code, annealing method and other information such as MR T-3 CA), size (the default order is thickness * width * length, tin plating amount ((different thickness plating) Tin needs to add A/D as the marking line mark, if not, no marking line will be marked), surface, order quantity, etc.

When ordering tin plating, please confirm with our sales staff the end use, such as canbody, ends, twist off caps, crown cork, EOE, etc., as well as the contents, special contents such as milk powder, high protein food, mushrooms, fruits, etc.; -

Single Reduced Cold-Rolled Tinplate Coil - Stock Warehouse

-

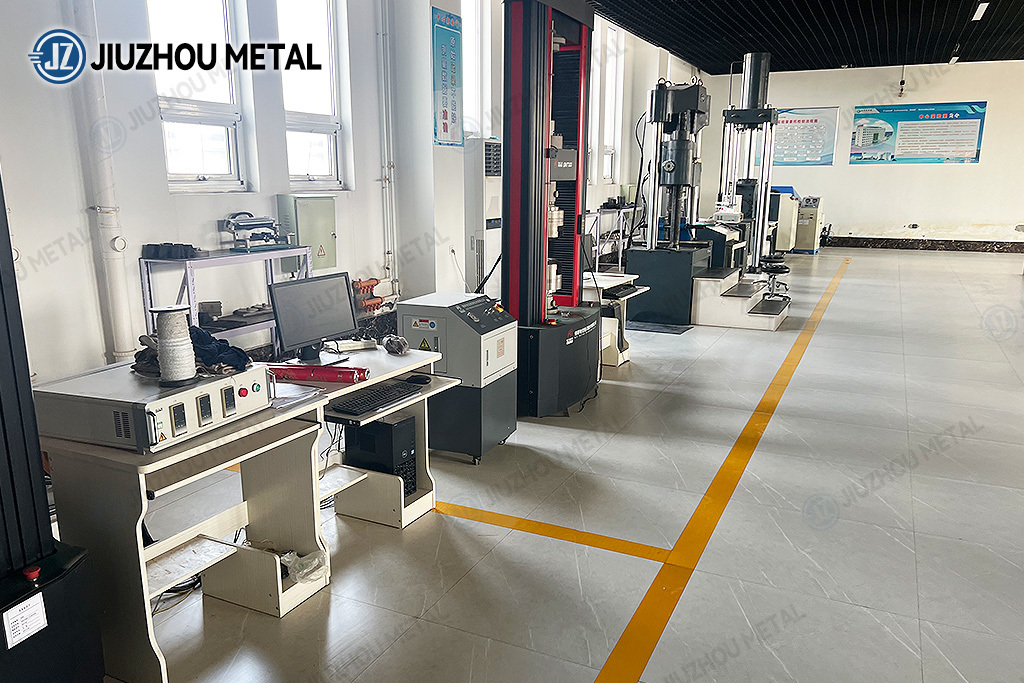

Single Reduced Cold-Rolled Tinplate Coil - Product Inspection

Tensile Strength Testing Tensile Strength Testing Physical Performance Testing Chemical Composition Testing

Inspection Hardness Testing Spectral Detection Mechanical Properties -

Single Reduced Cold-Rolled Tinplate Coil - Product Measurement

Thickness measurement Thickness measurement Thickness measurement Width measurement Measurement Measurement Measurement Measurement -

Single Reduced Cold-Rolled Tinplate Coil - Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote