Crosshead Forging

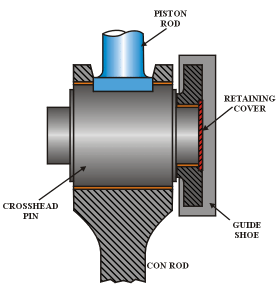

The crosshead is a component that connects the piston and connecting rod, and has a guiding effect. A large number of compressors use connecting rod small ends.

- Product Description

- Spot Warehouse

- Product Inspection

- Product Measurement

- Product Packaging

-

- Commodity name: Crosshead Forging

The crosshead is a component that connects the piston and connecting rod, and has a guiding effect. A large number of compressors use connecting rod small ends.

Crosshead Forging Description

The purpose of the crosshead is to translate reciprocating motion of the piston into the semi rotary motion of the con rod and so bearings are required. It is also necessary to provide guides in order to ensure that the side thrust due to the conrod is not transmitted to the piston. This also ensure the piston remains central in the cylinder thus limiting wear in the liner.

Two faces are required as the thrust acts in opposite directions during power and compression stroke. Guide shoes positioned at the extreme ends of the crosshead pin provided a large area and minimise risk of twisting. The doxford engine uses a centrally positioned shoe because there is no room at the ends of the pin due to the side rod crossheads.

Crosshead Guides

The usual way of checking guide clearance is by means of a feeler gauge with the piston forced hard against one face and the total clearance taken at the other face. This gives a reasonable estimation as wear should be approximately the same in the ahead and astern faces. A more accurate idea can be gained by chocking the piston centrally in its bore than measuring the clearance at each face. This will also give the athwartships alignment. The edges of the guide shoes are also white metal faced and these run against rubbing strips. Clearance at these faces can be checked with feelers and this gives the fore and aft alignment.

Guide clearances are usually adjusted by means of shims between the hardened steel guide bars and the mounting points. Bolts are slackened off allowing slotted shims to be inserted or removed. Note, care must be taken when handling these shims.

Crosshead pins are supported in bearings and the traditional way has been to mount the piston rod at the centre of the pin with a large nut and having two bearings alongside. This arrangement is like a simply supported beam and the pin will bend when under load. This gives rise to edge pressures which break through the oil film resulting in bearing failure. The Sulzer solution is to mount the bearings on flexible supports. When the pin bends the supports flex allowing normal bearing contact to be maintained.

-

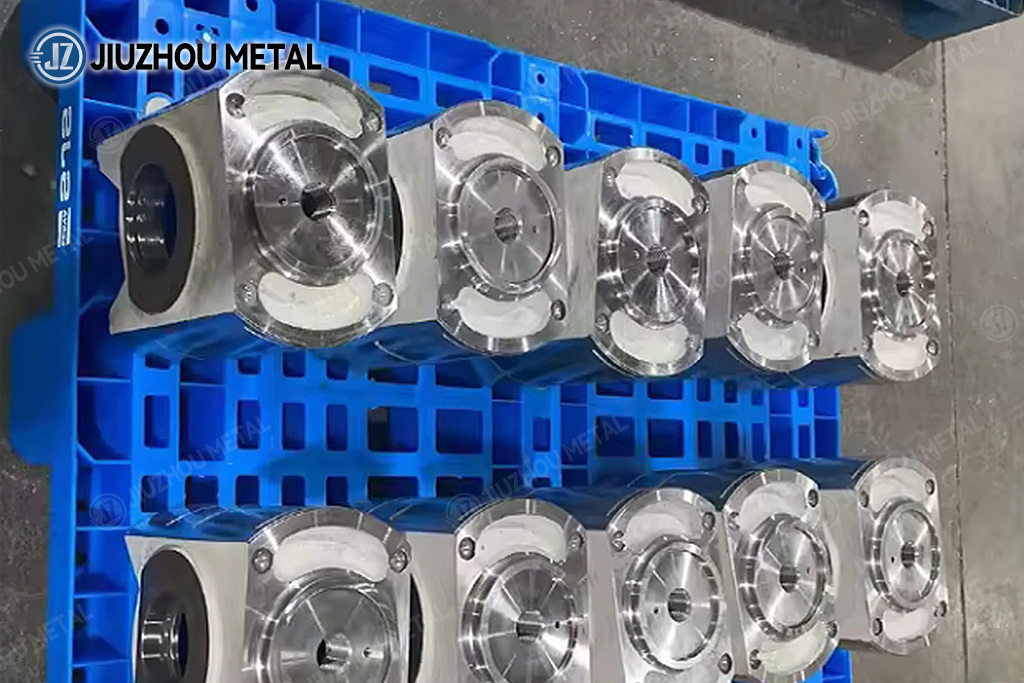

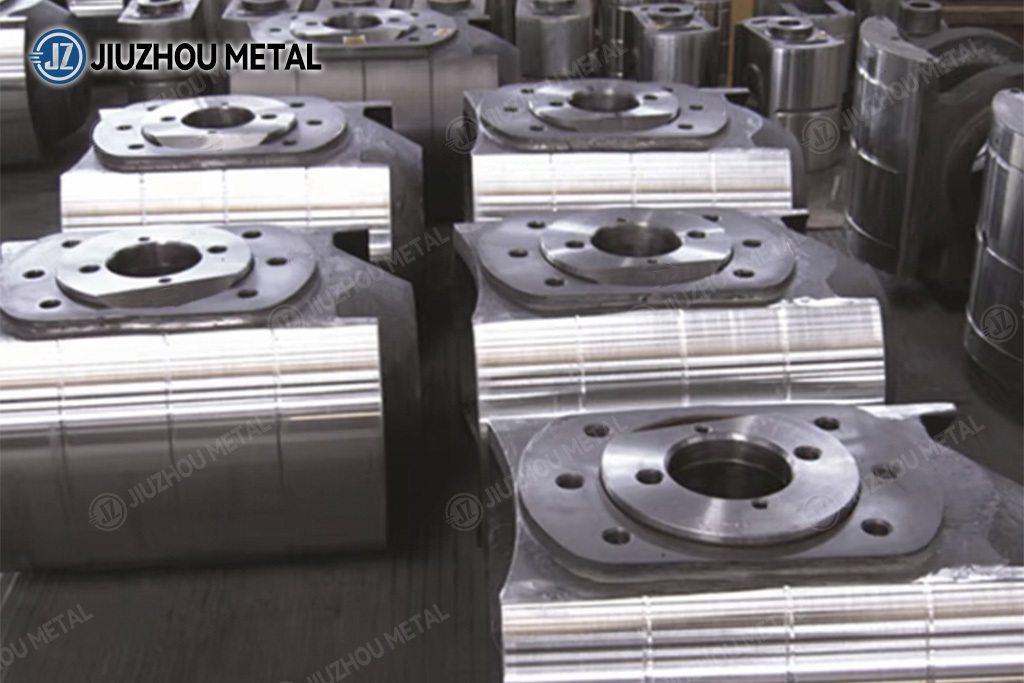

Crosshead Forging - Stock Warehouse

-

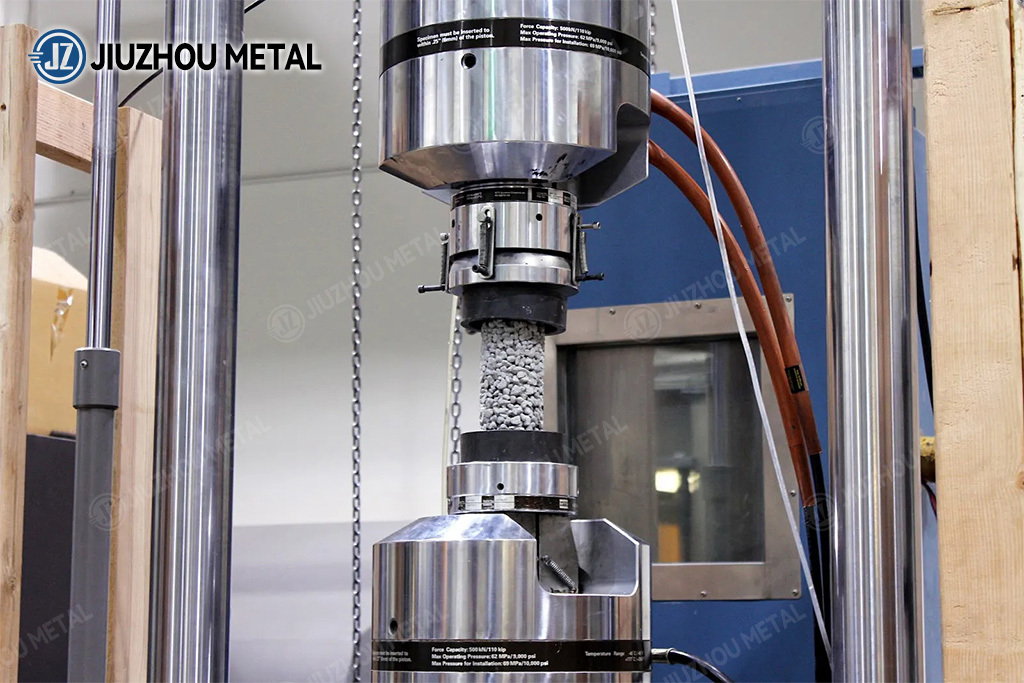

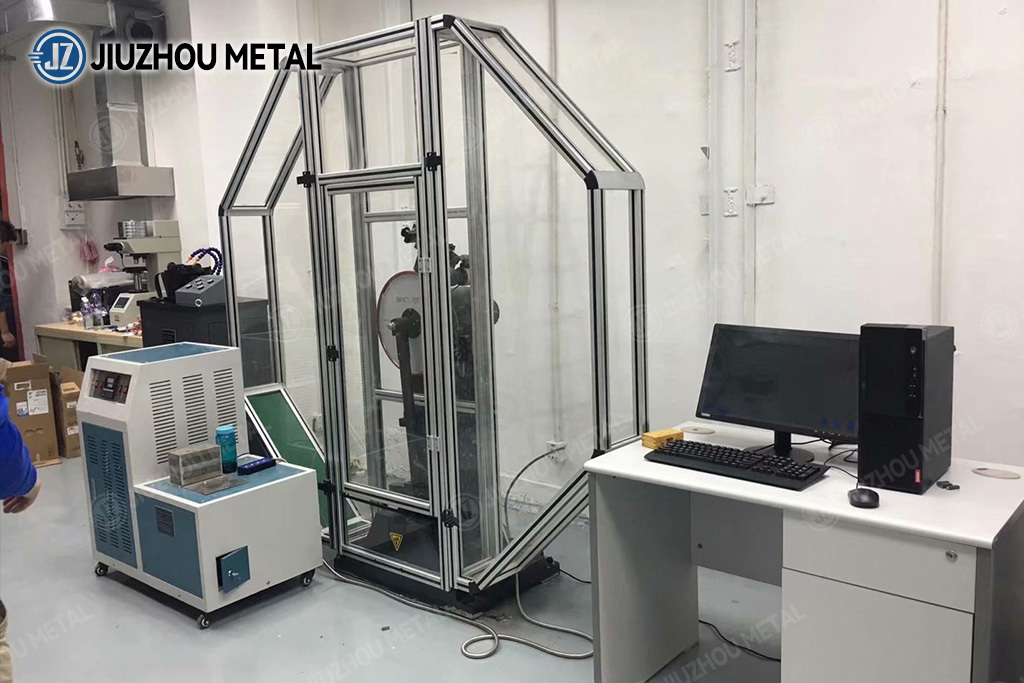

Crosshead Forging - Product Inspection

Stress-rupture-testing Tensile-testing Hardness-testing Chemical Composition Testing

Inspection Magnetic-particle-inspection Charpy-impact-testing Ultrasonic-testing -

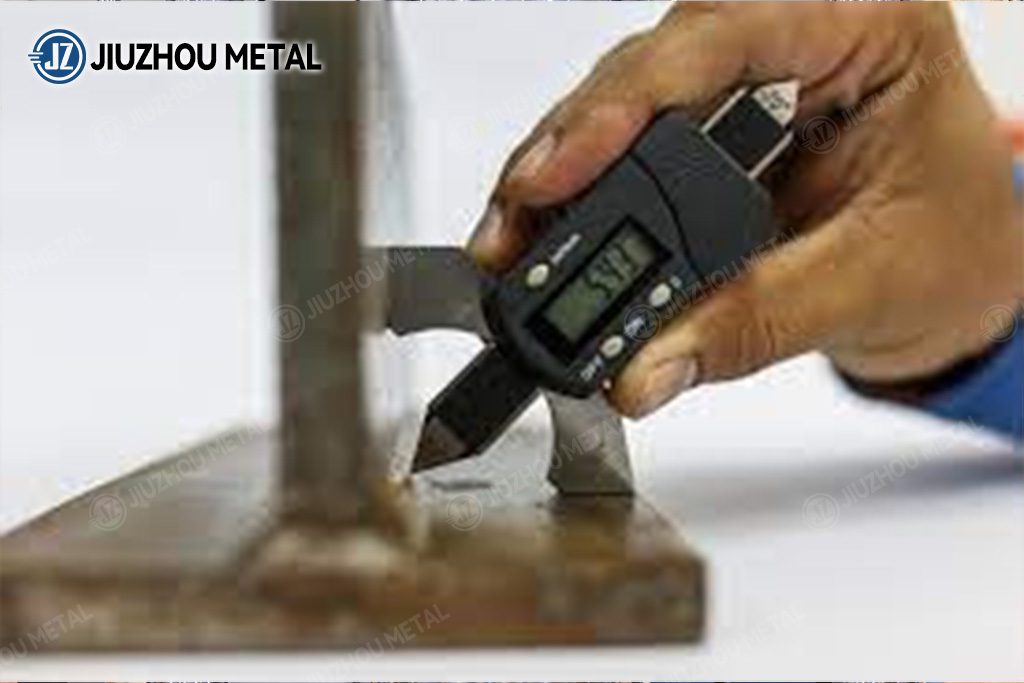

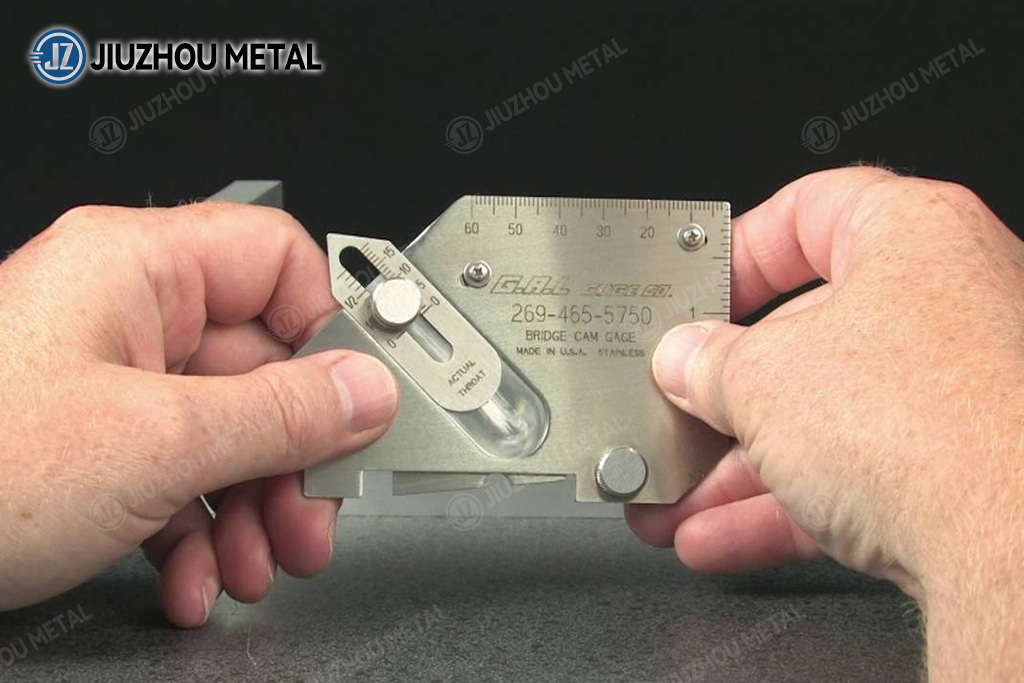

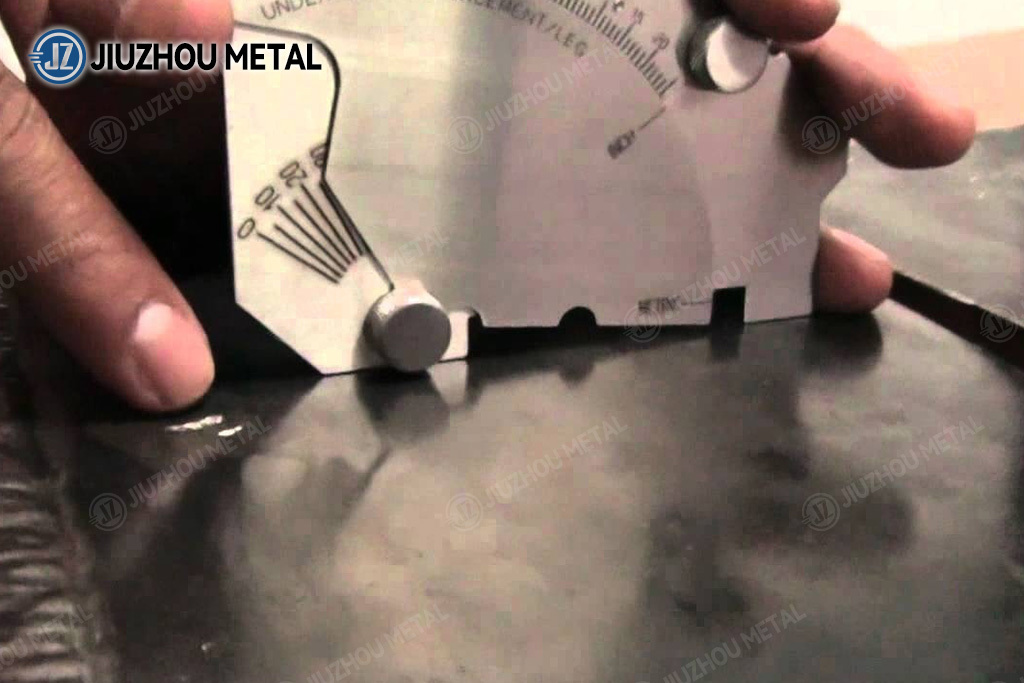

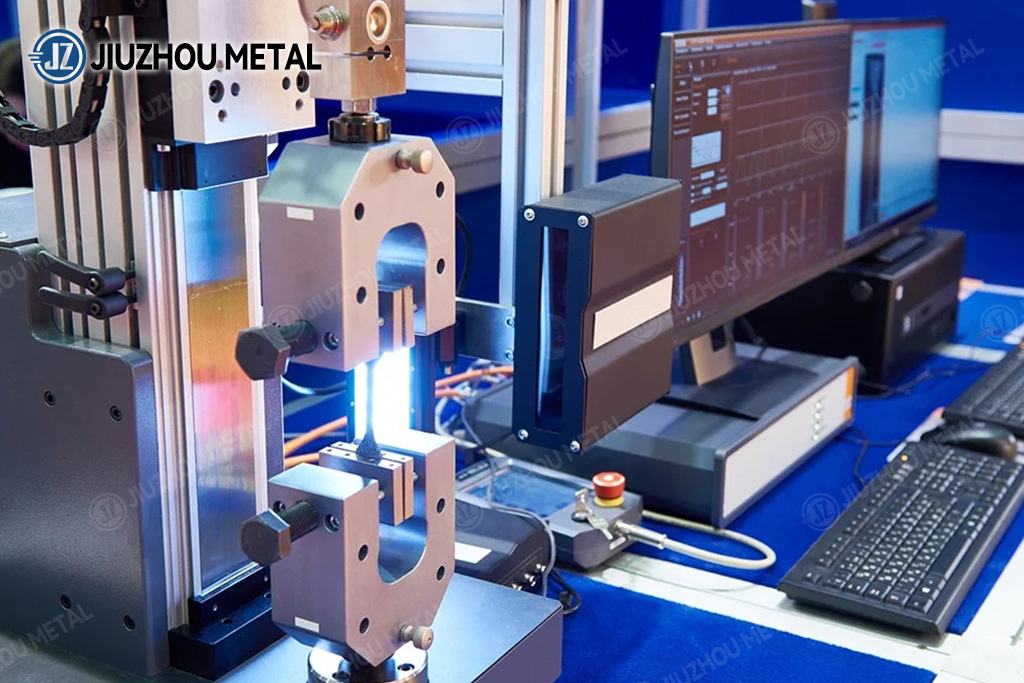

Crosshead Forging - Product Measurement

Measurement Measurement Measurement Measurement Measurement Measurement Measurement Measurement -

Crosshead Forging - Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote