Piston Rod - Marine Forgings

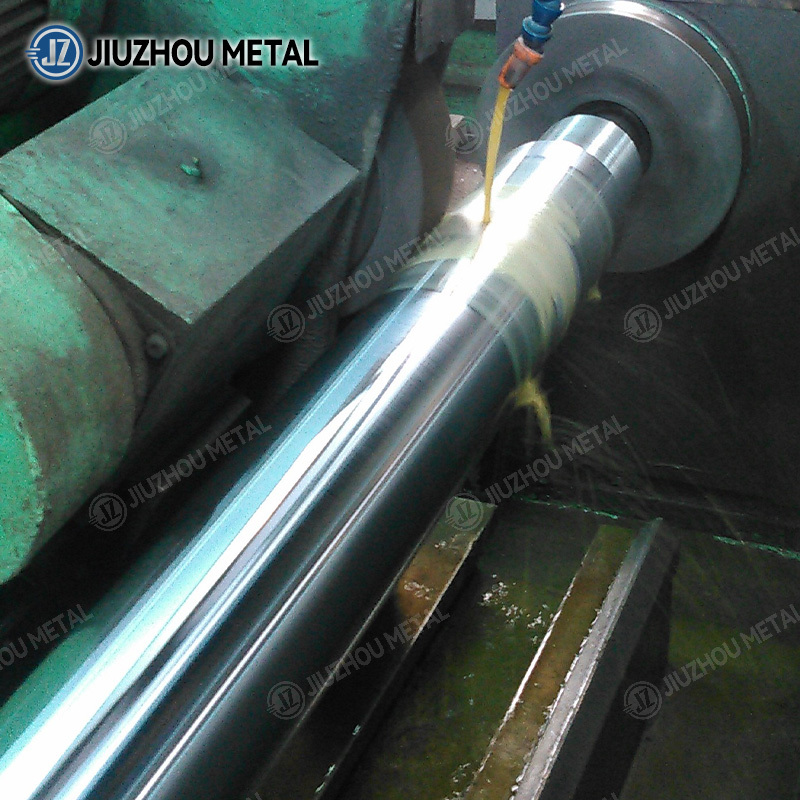

This product is a piston rod used to open and close hutch in the marine vessel. Subject product is destined to be used on the sea, thus the product is given enough surface finishing having the strong corrosion resistance against salt damage and to satisfy the abrasion resistance as well. After the surface finishing, the rod is given integrated in-house machining and grinding in order to up-grade sliding ability.

- Product Description

- Spot Warehouse

- Product Inspection

- Product Measurement

- Product Packaging

-

- Commodity name: Piston Rod - Marine Forgings

This product is a piston rod used to open and close hutch in the marine vessel. Subject product is destined to be used on the sea, thus the product is given enough surface finishing having the strong corrosion resistance against salt damage and to satisfy the abrasion resistance as well. After the surface finishing, the rod is given integrated in-house machining and grinding in order to up-grade sliding ability.

Piston Rod - Marine Forgings Description

There are many types of piston rods, and each has its own advantages and disadvantages. Here are the most common types of piston rods:

● Conventional pistons: These pistons use a standard piston ring and cylinder. They’re the most common type of piston, and they’re also the cheapest. Conventional pistons have some disadvantages, though. They tend to wear out quickly, and they can’t handle high temperatures very well.

● Overhead cam: Overhead cam pistons use a camshaft to raise and lower the valvetrain. This allows them to handle higher temperatures than conventional pistons, and it also gives them better performance in terms of acceleration and top speed. However, overhead cam pistons are more expensive than conventional pistons, and they tend to be less durable.

● Multiport: Multiport pistons have two or more ports that allow them to breathe better. This makes them better at handling high temperatures than conventional pistons, but it also means they’re slower. Multiport pistons are also more expensive than conventional pistons.

Added Characteristics Corrosion resistance, Abrasion resistance Industry Others Processing Service Plating, Grinding Size Weight φ100~φ250, L: 300~L: 2,000, 30kg~500kg Base Metal Iron Commonly Used Piston Rod Material

1.45# Steel ( C45 , SAE1045 ) Material

45# steel is a high-quality carbon structure steel, the hardness is not high and easy to cut, after quenching, its surface hardness can reach 45-52HRC. And it can also have better cutting performance and higher strength, toughness and other comprehensive mechanical properties, so it is one of the commonly used materials for shaft parts.2.40Cr Steel

40Cr steel is also a more commonly used material in the production of piston rods, it is not only a medium carbon tempered steel, but also a cold heading die steel. It has good comprehensive mechanical properties and is generally suitable for the manufacturing of shaft parts with medium precision and high speed.3.Stainless Steel

Stainless steel has the characteristics of resistance to air, steam, water and other weak corrosive media, commonly used 304, 316, 402 these materials. theseThe weldability, polishing, heat resistance, corrosion resistance, corrosion resistance are relatively good, through precision cold drawing, fine grinding, high precisionDegree polishing and other processes, the technical indicators of the piston rod manufactured by it are in line with and exceed national standards, so it is often used in hydraulic cylinders. -

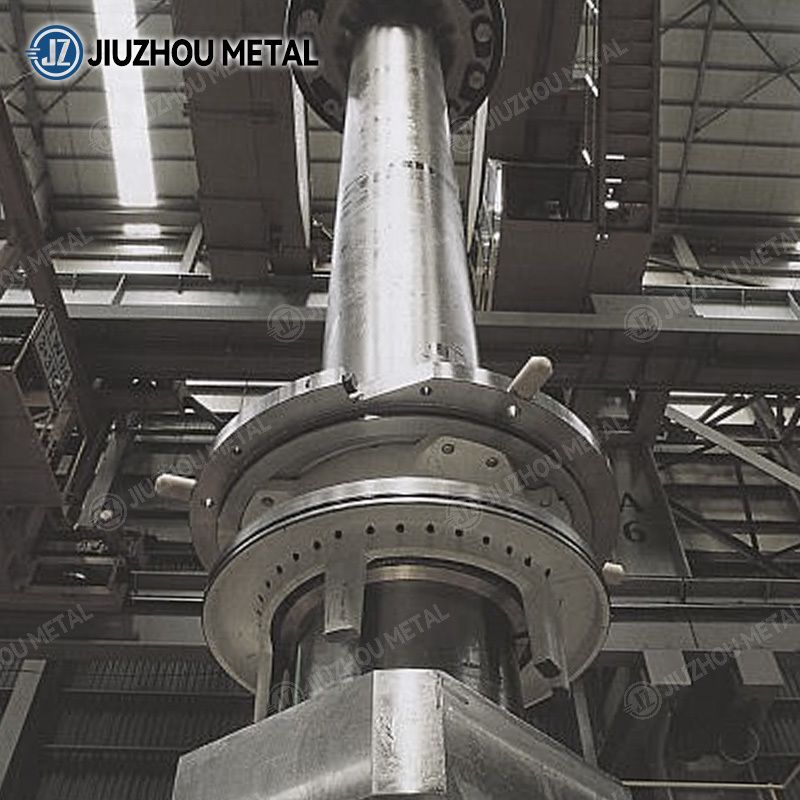

Piston Rod Marine Forgings - Stock Warehouse

-

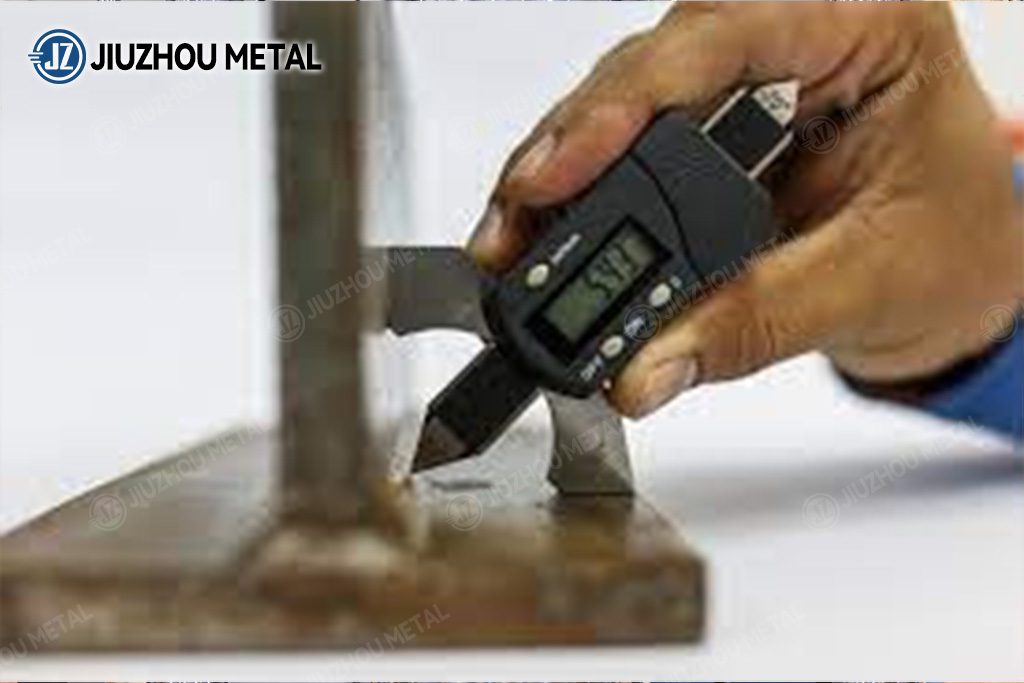

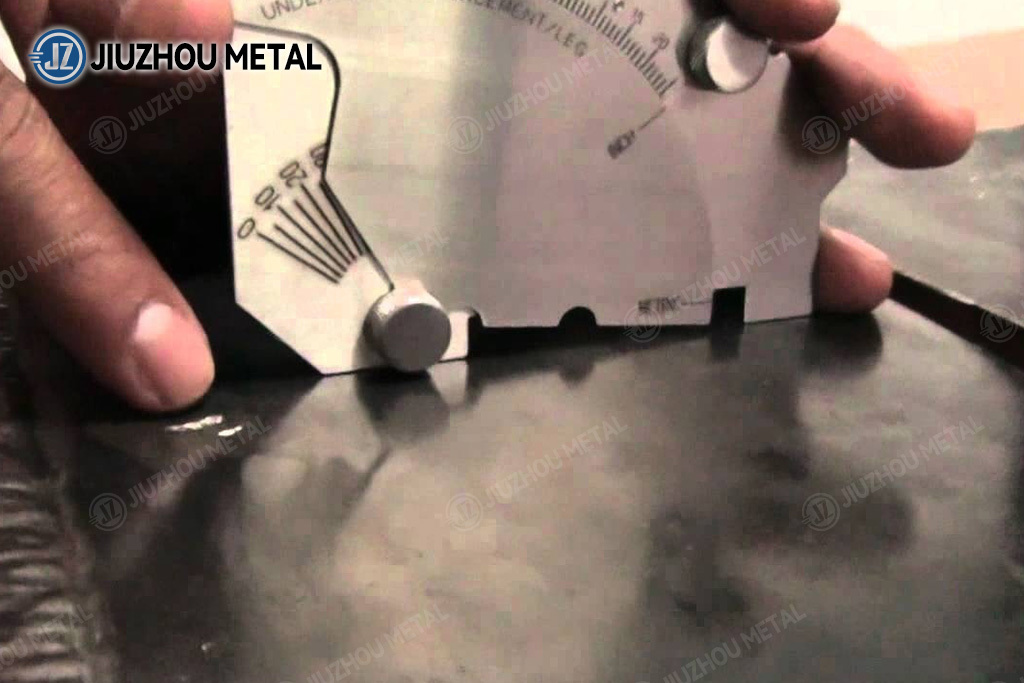

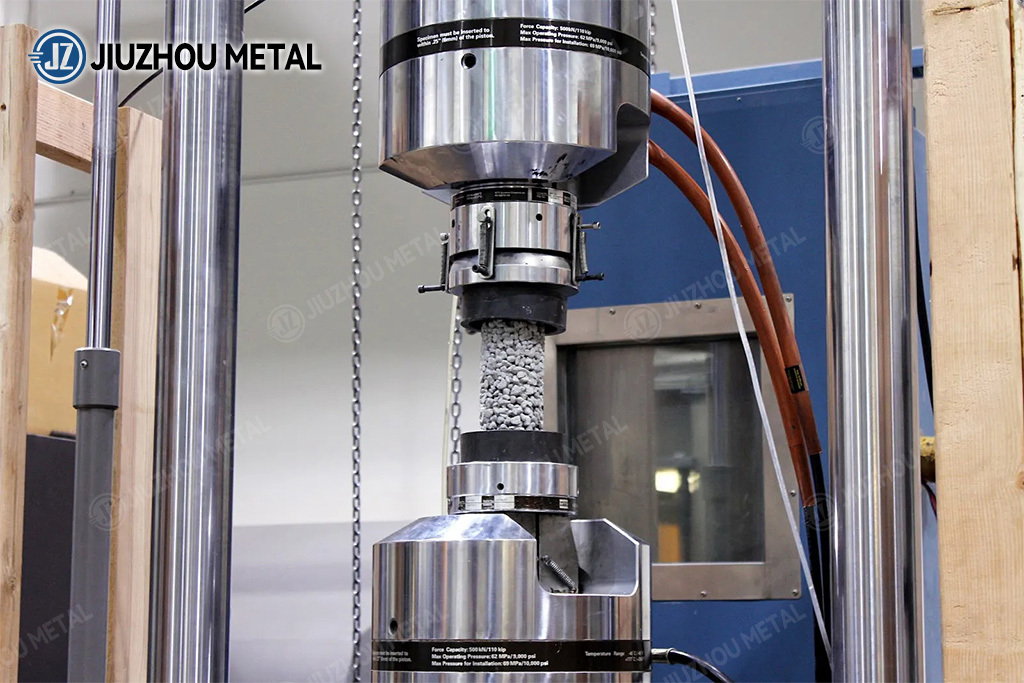

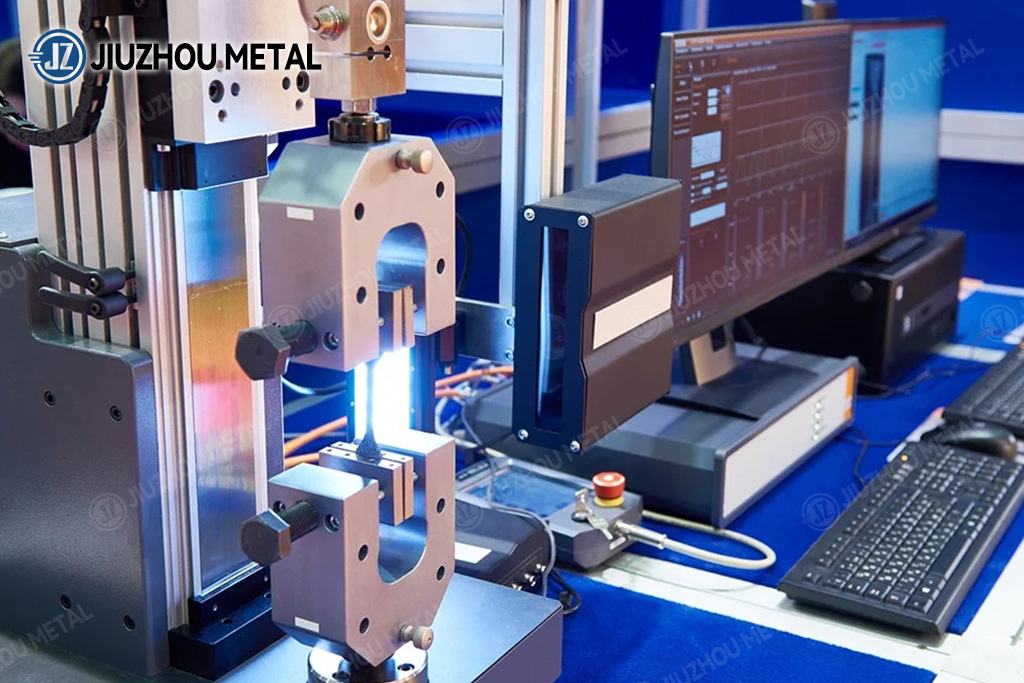

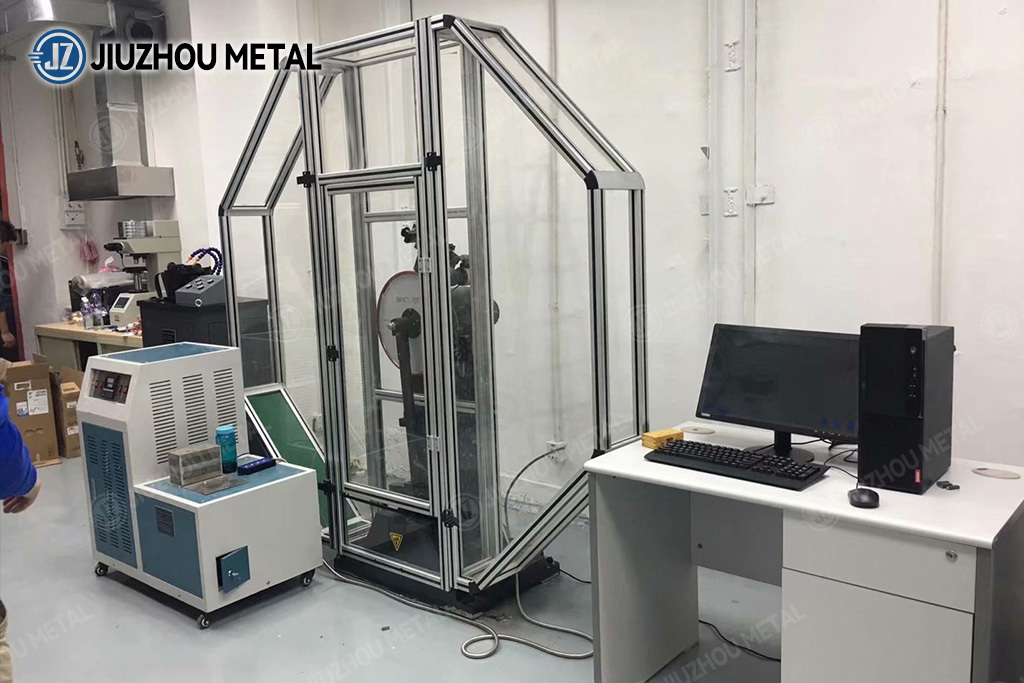

Piston Rod Marine Forgings - Product Inspection

Stress-rupture-testing Tensile-testing Hardness-testing Chemical Composition Testing

Inspection Magnetic-particle-inspection Charpy-impact-testing Ultrasonic-testing -

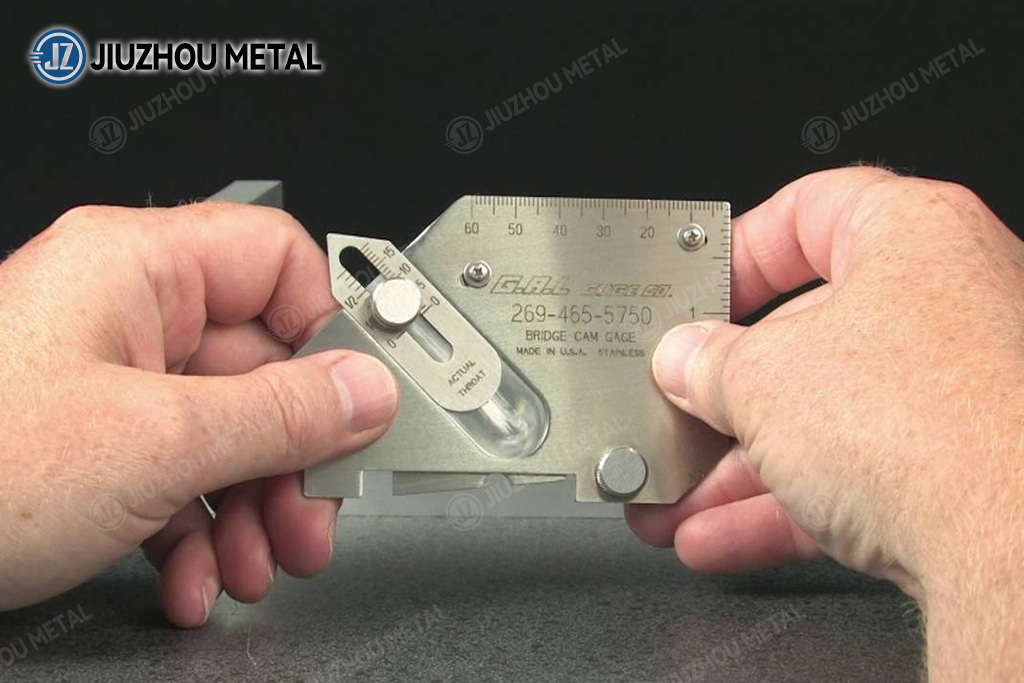

Piston Rod Marine Forgings - Product Measurement

Measurement Measurement Measurement Measurement Measurement Measurement Measurement Measurement -

Piston Rod Marine Forgings - Product Packaging

Baowu Special steel

Your reliable steel supplier

Baowu Special steel has 10+ warehouses with ready stock. The annual supply capacity is approximately 10 million tons. It has 10 years of experience in large-scale project supply. The customer reorder rate reaches 86%. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase.

Get A Quote